Table 1

Catalytic production of quinoxalines from carbohydrates and their derived feedstocksa

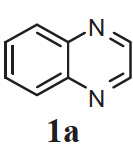

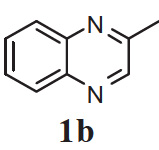

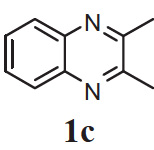

| Entry | Carbohydrate or its derivative | Catalyst or additive | Temp. (ºC) | Time (h) | Yield of quinoxalines (%)b | |||

|

|

|

Total | |||||

| 1 | Glucose | − | 150 | 5 | 13 | 33 | 6 | 52 |

| 2 | Glucose | − | 180 | 5 | 19 | 50 (46) | 11 | 80 |

| 3 | Glucose | − | 120 | 18 | 7 | 19 | 2 | 28 |

| 4c | Glucose | AlCl3/SnCl2 | 180 | 4 | 18 | 12 | 7 | 37 |

| 5d | Glucose | Sn-Beta | 180 | 5 | 19 | 51 | 11 | 81 |

| 6 | Glucose | Na2CO3 | 180 | 5 | 3 | 55 | 5 | 63 |

| 7 | Glucose | K2CO3 | 180 | 5 | 3 | 65 | 4 | 72 |

| 8 | Glucose | LiOH | 180 | 5 | 3 | 51 | 2 | 56 |

| 9 | Glucose | NaOH | 180 | 5 | 6 | 64 | 7 | 77 |

| 10 | Glucose | KOH | 180 | 5 | 6 [6] | 66 [67] (64) | 7 [6] | 79 |

| 11 | Glucose | Ca(OH)2 | 180 | 5 | 8 | 65 | 4 | 77 |

| 12 | Fructose | KOH | 180 | 5 | 7 | 67 | 7 | 81 |

| 13 | Mannose | KOH | 180 | 5 | 6 | 65 | 8 | 79 |

| 14 | Pyruvaldehyde | − | 180 | 0.25 | 2 | 95 | 0 | 97 |

| 15 | Glyceraldehyde | − | 180 | 2 | 6 | 51 | 1 | 58 |

| 16 | Dihydroxyacetone | − | 180 | 2 | 5 | 85 | 0 | 90 |

| 17 | Lactic acid | − | 180 | 4 | 0 | 0 | 0 | 0 |

a: Reaction conditions: carbohydrate feedstock (0.5 mmol), o-PDA (2 mmol), H2O (20 mL), N2 (2 MPa). For the reactions with alkalis, 0.15 mmol alkali was employed except for Ca(OH)2 (7.5 × 10−2 mmol instead). b: Yields are based on average value from duplicate experiments with error <2%, determined by gas chromatography (GC). Values in parentheses and brackets indicate the isolated and NMR yields, respectively. c: AlCl3 and SnCl2 (10 mol% each) were employed. d: Sn-Beta (3 mol%, based on Sn content) were employed. Mass balance is not complete due to undesired competitive reactions of the Maillard type and/or caramelization.

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.