| Issue |

Natl Sci Open

Volume 4, Number 3, 2025

Special Topic: Thermoelectric Materials and Devices

|

|

|---|---|---|

| Article Number | 20250005 | |

| Number of page(s) | 10 | |

| Section | Materials Science | |

| DOI | https://doi.org/10.1360/nso/20250005 | |

| Published online | 30 April 2025 | |

RESEARCH ARTICLE

Robust mechanical properties of Ag2Se1–xTex thermoelectric materials

1

State Key Laboratory of Metal Matrix Composites, School of Materials Science and Engineering, Shanghai Jiao Tong University, Shanghai 200240, China

2

Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China

3

School of Materials Science and Engineering, University of Science and Technology of China, Hefei 230026, China

4

Wuzhen Laboratory, Tongxiang 314500, China

5

State Key Laboratory of High Performance Ceramics and Superfine Microstructures, Shanghai Institute of Ceramics, Chinese Academy of Sciences, Shanghai 200050, China

* Corresponding authors (emails: This email address is being protected from spambots. You need JavaScript enabled to view it.

(Tian-Ran Wei); This email address is being protected from spambots. You need JavaScript enabled to view it.

(Zhenyu Pan); This email address is being protected from spambots. You need JavaScript enabled to view it.

(Xun Shi))

Received:

4

February

2025

Revised:

15

April

2025

Accepted:

18

April

2025

High mechanical robustness is essential to the material’s processibility for the applications in flexible and miniaturized electronics. As state-of-the-art room-temperature thermoelectric materials, Ag2Se1–xTex alloys exhibit superior thermoelectric transport properties but their mechanical properties remain largely unexplored. Herein, we systematically investigate the mechanical and thermoelectric properties of a series of Ag2Se1–xTex materials. Among them, Ag2Se0.9Te0.1 shows robust mechanical properties including a large compression strain of (26.7 ± 4.5)%, a high compression strength of (279.2 ± 49) MPa, and an excellent fracture toughness of (4.5 ± 0.6) MPa m1/2. These robust mechanical properties are ascribed to the dense dislocations as well as possible sub-grain rotations. Combined with the excellent thermoelectric figure of merit, zT of 0.78 at 300 K and 1.1 at 380 K, the Ag2Se1–xTex alloys are promising candidates for robust and efficient thermoelectric applications near room temperature.

Key words: thermoelectric / Ag2Se-Ag2Te / mechanical properties

© The Author(s) 2025. Published by Science Press and EDP Sciences.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

INTRODUCTION

Thermoelectric materials enable the direct conversion between heat and electricity, providing a promising solution for green energy utilization and environmental protection [1,2]. The past two decades have witnessed the blossom of a variety of high-performance thermoelectric materials [3–7] along with new theories and design strategies. In recent years, thermoelectric technology has widely expanded its realm and found new applications in several booming industries, especially the self-powered flexible and nano/micro-scale electronics used as physiological monitors and wearable intelligent sensors [8,9]. To meet these conditions, thermoelectric materials are required to possess both a high zT (defined as zT = S2σT/κ, where S, σ, T, and κ represent the Seebeck coefficient, electrical conductivity, absolute temperature, and thermal conductivity, respectively) and robust mechanical properties around room temperature to ensure decent processibility and deformability [10,11].

Traditional high-performance thermoelectric materials are typically brittle. For example, Bi2Te3-based polycrystalline alloys, the best room-temperature thermoelectric materials, show a small compressibility of merely ~5% [6,12–19]> (Figure 1). As a consequence, seeking mechanically robust thermoelectric materials is a long-standing goal for promoting the application of thermoelectric devices. Fortunately, among the promising room-temperature thermoelectric materials, the Ag2Se and Ag2Te compounds are reported to show decent mechanical properties [20–28]: the compression strength and ultimate strain values can reach approximately 275 and 160 MPa, 40% and 20% for high-quality Ag2Se and Ag2Te samples, respectively. Interestingly, a large elongation of around 43% was found in nano-sized Ag2Te material [26]. The introduction of domains and secondary phases was also employed to enhance the mechanical properties [23,27,28]. In addition to the pristine compounds, alloying is a classic and effective method to modulate transport and mechanical properties [29]. Feng et al. [26] studied the mechanical properties of Te-rich Ag2(Te, Se) alloys, i.e., Ag2Te0.92Se0.08, Ag2Te0.88Se0.12, and Ag2Te0.8Se0.2. The compression strains range from 10% to 22% and the strengths are 92–160 MPa.

|

Figure 1 (A) Average values of the compression strength and ultimate strain for Ag2Se1–xTex samples in this work (red stars); data of Ag2Se [27,28,33], Ag2Te [23,26], Ag2Te1–ySey [26] and Bi2Te3-based polycrystalline thermoelectric materials [6,12–14,17–19] are included for comparison. Raw data are listed in Table S1. (B) Comparison of mechanical and physical properties between Ag2Se0.9Te0.1 and typical Bi2Te3-based polycrystalline thermoelectric materials [6,12]. |

Despite the above progress, the understanding of the mechanical properties of Ag2(Se, Te) is still quite inadequate in terms of several aspects. Firstly, several key mechanical properties, such as fracture toughness and energy absorption, are overlooked in previous studies while these parameters are particularly important to evaluate materials ability to resist crack propagation. Secondly, for the Ag2Se-Ag2Te alloys, the mechanical study focuses only on Te-rich compositions (from Ag2Te to Ag2Te0.8Se0.2) [26] while a wide range of compositions remain to be explored. In addition, the underlying deformation mechanisms for this system need further exploration.

In this study, we comprehensively investigate the mechanical properties of Ag2Se-Ag2Te series materials, in terms of a wide range of compositions and diverse mechanical behaviors. It is found that this series of high-performance thermoelectric materials combines decent compressibility, strength, and toughness. As a case study, the high-performance Ag2Se0.9Te0.1 material shows superior mechanical properties. Particularly, the fracture toughness of (4.5 ± 0.6) MPa m1/2 is larger than typical thermoelectric counterparts like (Bi, Sb)2Te3, MgAgSb and Mg3(Sb, Bi)-based materials [6,30,31]. Detailed microstructural analyses reveal that the large compressibility and toughness should originate from the dislocation multinucleation as well as the sub-grain rotation. This work demonstrates Ag2Se1–xTex materials as promising thermoelectric materials with high performance and toughness for durable and stable thermoelectric devices.

MATERIALS AND METHODS

A series of Ag2Se1–xTex samples were synthesized by a melting and annealing process followed by spark plasma sintering (SPS). High-purity elements Ag (shots, 99.99%, Alfa Aesar), Se (shots, 99.999%, Aladdin), and Te (shots, 99.999%, Aladdin) were weighted and then sealed in quartz tubes under vacuum. Slight Ag deficiencies were introduced in this procedure to finely tune the transport properties. The quartz tubes were slowly heated to 1273 K and kept at this temperature for 12 h. Afterwards, the tubes were cooled down to 1023 K over 25 h, and then to 723 K. After being dwelled at 723 K for 72 h, the tubes are naturally cooled down to room temperature. The as-prepared ingots were ground into powders under liquid nitrogen and dried in the oven at 338 K for 24 h to remove moisture. Powders were then consolidated by SPS at 623 K under the pressure of 55 MPa for 10 min.

The X-ray diffraction (XRD) was carried out with the Cu-Kα source with a scanning speed of 4°/min. The sample morphologies were examined by field emission scanning electron microscopy (FESEM, TESCAN RISE-MAGNA), along with energy dispersive X-ray analysis to observe elemental distribution. The transmission electron microscope (TEM) was characterized by FEI Talos F200X. The electrical conductivity and Seebeck coefficient were measured using ZEM-3 (Advanced Riko, Japan). The thermal conductivity was obtained via κ = λ × Cp × d, where λ is thermal diffusivity measured by Netzsch LFA-457, Cp is the heat capacity estimated by the Dulong-Petit law, and the density d was measured using Archimedes method. The differential scanning calorimetry was conducted on Netzsch DSC 404. The carrier concentration was measured by Lakeshore 8400 series using the van der Pauw method. The confocal laser scanning microscope test for the surface was performed on ZEISS LSM 900. Compression, three-point bending and fracture toughness tests were performed on SHIMADZU AGS-X. The specimen size is about 3 mm × 3 mm × 6.5 mm for compression with a constant strain rate of 0.005 min–1, 2 mm × 1 mm × 18 mm for three-point bending and 3 mm × 2 mm × 18 mm with pre-crack length of 1.1 mm for fracture toughness. The loading speed for three-point bending and fracture toughness tests was set at 0.1 mm/min. The sound velocity data were measured by the ultrasonic measurement system UMS-100 with transverse wave transducers of 5 MHz and longitudinal wave transducers of 10 MHz.

RESULTS

Phase structures

For the Ag2Se1–xTex samples, the XRD patterns (Figure S1) are indexed to the Ag2Se-based orthorhombic structure and Ag2Te-based monoclinic structure when x < 0.7 and x > 0.7, respectively. For the composition of x = 0.7, the diffraction peaks are mainly indexed to Ag2Se structure but a minor Ag2Te-structured phase is also observed, indicating a mixed phase (also see Figure S2 for XRD refinement). The peaks shift to lower angles with increasing Te content in the Ag2Se-structure region, which validates the alloying effect of Te in enlarging the lattice. All the Ag, Se, and Te elements show a homogeneous distribution as shown in Figure S1. With increasing Te content, the orthorhombic-to-cubic transition temperature slightly varies between 407 and 410 K as reflected by the DSC analysis (Figure S1). For the Ag2Se0.3Te0.7 mixed-phase sample, two distinct endothermic peaks appear. This phase transition composition is also consistent with previous reports [32].

Mechanical properties

The compression stress-strain curves of Ag2Se1–xTex samples are shown in Figure S3. Although there is a certain degree of data scattering, the average values are still useful for comparison. For both Ag2Se and Ag2Te, the average compression strength and strain well exceed 200 MPa and 30%, among the highest reported data for the two materials [23,33]. Compared with the pristine binary compounds, both the strength and compressibility decrease for the alloys, except two compositions: Ag2Se0.9Te0.1 and Ag2Se0.3Te0.7 (Figures 1A and 2A). As summarized in Figure 1A, the Ag2Se1–xTex alloys are obviously more compressible and stronger than Bi2Te3-based materials (see raw data in Table S1). Taking Ag2Se0.9Te0.1 as a typical case, the average compression strength is as high as 279.2 MPa and the average strain is 26.7%. For a couple of samples, the largest strength and strain can even reach around 300 MPa and 29%, respectively (Figure S3). The three-point bending test results are shown in Figure S3(i). The composition-dependent bending strength of the alloys is consistent with the compression strength. The Ag2Se sample exhibits the maximum fractured bending strain of around 3% while other compositions show the values around 1%, a sign of brittle behavior in bending. The difference between bending and compression behaviors is well expected considering the different stress states.

|

Figure 2 (A) Compression strength, compression strain and bending strength for Ag2Se1–xTex samples. (B) Fracture toughness KIC for Ag2Se1–xTex samples; data of Bi0.5Sb1.5Te3 [6], Mg3Sb1.3Bi0.7 [31], PbTe [34] are also given for comparison. (C) Schematic illustration of energy absorption (modulus of toughness) for Ag2Se under compression test. (D) Modulus of toughness for Ag2Se, Ag2Se0.9Te0.1 and other typical thermoelectric materials [12,30,35]. The error bars in panels A, B, and D denote the standard deviation from multiple measurements. |

The fracture toughness KIC, the ability to resist the propagation of the crack, is also measured on single-edge notch-bending specimens (see the calculation detail in Supplementary Data). As shown in Figure 2B, the KIC values share the similar tendency with the strength. The highest value of (4.5 ± 0.6) MPa m1/2 appears at the composition Ag2Se0.9Te0.1, which is higher than other thermoelectric materials like BiSbTe (0.9 MPa m1/2) [6], PbTe (0.59 MPa m1/2) [34], and Mg3Sb1.3Bi0.7 (3.0 MPa m1/2) [31]. Moreover, the integral of the area under stress-strain curves is often used to represent the total energy absorbed per unit volume up to failure as shown in Figure 2C. This value is termed as modulus of toughness, giving the overall measure of materials’ ability to withstand both elastic and plastic deformation [35]. This parameter is especially important when facing a significant amount of impact. As shown in Figure 2D, this value is derived as (65 ± 16) MJ m–3 for Ag2Se and (55 ± 17) MJ m–3 for Ag2Se0.9Te0.1 from the compression stress-strain curve, much larger than most traditional thermoelectric materials. The high KIC and modulus of toughness clearly indicate the tough and robust character of the materials.

Figure S5 shows the composition-dependent bulk modulus (B) and shear modulus (G) that are obtained from the measured sound speed. The bulk modulus is around 64 GPa for Ag2Se and 48 GPa for Ag2Te, which are comparable with the clathrate Ba8Ga16Ge30 (66 GPa) and Mg3Sb2-based materials (45 GPa), and larger than hot-deformed Bi2Te3-based materials (ranging from 29 to 39 GPa) [6,36,37]. The alloyed samples show a slight decrease in modulus, which is consistent with the compression strength in Figure 2A.

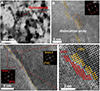

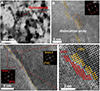

Microstructural analysis

We perform detailed microstructural analyses to understand the origin of these robust mechanical properties. As shown in Figures S6 and S7, clear slip bands appear after compression for typical compositions Ag2Se0.9Te0.1, Ag2Se and Ag2Te. In contrast, the bent samples exhibit intergranular fracture morphologies (Figure S4), suggesting the brittle behavior. Obvious dislocation lines are observed in broad regions in compressed Ag2Se0.9Te0.1 (TEM bright-field image, Figure 3A and Figure S8) and some are further identified as dislocation arrays in a single grain (HRTEM, Figure 3B). The formation of dislocation arrays indicates the multiplication, movements and accumulation of dislocations in Ag2(Se, Te) materials. The dislocation density estimated via the bright-field images is around 0.9 × 1014–2.1 × 1014 m–2 (Figure S8), which is a high density comparable with 10% tensile deformed Cu metal [38]. The dual effects of dislocations on mechanical properties of these materials can be understood from two aspects. On the one hand, the existence, motion, and multiplication of dislocations can well mediate the compressive deformation by sliding and multiplication, which changes the large local stress into a long-range diffuse stress field and prevents stress concentration [39]. On the other hand, these high-density dislocations accompanied with large lattice strains can also further impair the plasticity and enhance the strength by entangling with each other just like in metals [40].

|

Figure 3 Transmission electron microscope (TEM) analysis of Ag2Se0.9Te0.1 sample with a compression strain 10%. (A) Bright-field image showing typical dislocations marked by red arrows. (B) HRTEM image and corresponding FFT image highlighting the dislocation array. (C) HRTEM image illustrating two sub-grains; inset images are FFT images. (D) Grain interface of the red area in Panel (C); two sets of planes are marked as red and yellow dots, respectively. |

Besides dislocations (Figure 3A and B), other mechanisms also contribute to the large compressibility and toughness. As shown in Figure 3C and D, a straight and coherent boundary is observed between Grain 1 and Grain 2 of the compressed Ag2Se0.9Te0.1. The zone axes are  and

and  , respectively and the corresponding planes at the boundary are (113) and (

, respectively and the corresponding planes at the boundary are (113) and ( ), respectively (Figure 3D). It is speculated that when undergoing compressive stress, the partial region of one grain is rotated against the other part, thus forming sub-grains with straight, coherent boundaries with certain orientation differences. More HRTEM images with similar structures are given in Figure S9. Compared with randomly oriented boundaries, the formation of these coherent or semi-coherent boundaries can effectively reduce internal stress and favor the plastic deformation rather than fracture in compression. Similar grain boundaries are also observed in compressed Ag2Te as shown in Figure S10.

), respectively (Figure 3D). It is speculated that when undergoing compressive stress, the partial region of one grain is rotated against the other part, thus forming sub-grains with straight, coherent boundaries with certain orientation differences. More HRTEM images with similar structures are given in Figure S9. Compared with randomly oriented boundaries, the formation of these coherent or semi-coherent boundaries can effectively reduce internal stress and favor the plastic deformation rather than fracture in compression. Similar grain boundaries are also observed in compressed Ag2Te as shown in Figure S10.

Thermoelectric transport properties

The temperature-dependent thermoelectric properties are shown in Figure S11. The transport properties of silver chalcogenides are sensitive to the Ag/anion ratio and fabrication methods [41,42]. In this study, we tuned the stoichiometry through introducing Ag deficiencies to obtain the optimal performance (Figure S12). To be concise, the compositions are still denoted as their stoichiometric ones. The Ag2Se and Ag2Se0.9Te0.1 samples exhibit high power factor PF of around 25 μW cm–1 K–2 compared with other compositions. According to the |S|-nH plot (Pisarenko relation) shown in Figure 4A [43], the Ag2Se-structure compositions have a relatively small density-of-state effective mass md* = 0.23me as compared with other typical thermoelectric materials (e.g., 1.12me for Bi2Te2.7Se0.3 [44], 1.45me for GeTe [45], 2.3me for Cu2Se [3]). The small effective mass is beneficial for electrical transport properties, especially the mobility. As shown in Figure 4B, the room-temperature weighted mobility μW, an integrated electrical performance indicator, readily decreases for the alloys, being a sign of alloy scattering of electrons.

|

Figure 4 (A) Absolute Seebeck coefficient |S| versus carrier concentration nH for Ag2Se1–xTex materials at 300 K. Data of other Ag2Se-based materials are taken from Refs. [29,43]. The dashed line represents the calculated Pisarenko curve by the SPB model. (B) Relations of weighted mobility and lattice thermal conductivity with Te content; the dashed lines are calculated curves. (C) Temperature dependence of zT value for Ag2Se1–xTex samples with optimized Ag content. (D) zT value versus carrier concentration nH for Ag2Se1–xTex materials at 300 K. Data of other Ag2Se-based materials are taken from Refs. [29,43]. The dashed line represents the calculated Pisarenko curve by the SPB model. |

As to the lattice thermal conductivity κL, the electrical conductivity is so high that the calculation based on the Wiedemann-Franz law and SPB-derived Lorenz number often suffers from large uncertainties. Instead, we employ a κversusσ linear plot to derive κL as the intercept, which was proposed in our previous study [46] and illustrated in Figure S13. The κL firstly decreases from 0.66 W m–1 K–1 for Ag2Se and Ag2Se0.9Te0.1 to the minimum of 0.14 W m–1 K–1 for Ag2Se0.5Te0.5, and then increases to 0.6 W m–1 K–1 for Ag2Te, exhibiting a typical alloying effect trend [47] in which the mass and strain fluctuations can effectively scatter phonons. The variation of μw and κL with composition at room temperature is roughly fitted according to Ref. [48], which follows the relation of  . It is worth mentioning that the varying trend of μw and κL with the composition is also consistent with that of the modulus (Figure S5). This means that apart from the alloy scattering effect, the lattice softening by alloying is also at play.

. It is worth mentioning that the varying trend of μw and κL with the composition is also consistent with that of the modulus (Figure S5). This means that apart from the alloy scattering effect, the lattice softening by alloying is also at play.

Figure 4C shows the temperature-dependent zT for a series of Ag2Se1–xTex materials. Combining decent PFs and low thermal conductivity, the Ag2Se0.9Te0.1 material shows a high zT value of 0.78 at room temperature and 1.1 at 380 K. Using the single parabolic model [49], assuming the non-degenerate limit of mobility, μ0, as 2000 cm2 V–1 s–1 and lattice thermal conductivity as 0.6 W m–1 K–1, the theoretical curve of zTversusnH is plotted in Figure 4D. If the carrier concentration can be further optimized to 1 × 1018–2 × 1018 cm–3, the room-temperature zT will be further enhanced to above unity.

DISCUSSION

In this work, the phase structures, mechanical and thermoelectric properties of Ag2Se1–xTex alloys are studied. Te alloying transforms the orthorhombic Ag2Se into the monoclinic phase at the composition of x~0.7. The orthorhombic Ag2Se-rich materials exhibit higher thermoelectric performance, especially for the Ag2Se0.9Te0.1 sample. The zT value can reach 0.78 at room temperature and 1.1 at 380 K. Noticeably, Ag2Se0.9Te0.1 exhibits superior mechanical robustness with high strength of (279.2 ± 49) MPa, decent compressibility of (26.7 ± 4.5)%, and large fracture toughness of (4.5 ± 0.6) MPa m1/2. The robust mechanical properties are attributed to the dense dislocations and possible sub-grain rotations. These findings will advance the understanding of the mechanical properties of Ag2Se/Ag2Te-based alloys and help develop robust and efficient thermoelectric materials around room temperature.

Data availability

The original data are available from corresponding authors upon reasonable request.

Funding

Tian-Ran Wei was supported by the National Natural Science Foundation of China (92463310, 52373292). Tian-Ran Wei and Kunpeng Zhao were supported by the Zhejiang Provincial Natural Science Foundation of China (LD25E020001). Xun Shi was supported by the National Natural Science Foundation of China (52232010).

Author contributions

T.-R.W. and X.S. designed the research. H.C., S.R., and H.F. did the experiment. L.F. and Z.P. helped conduct the mechanical property test. H.C. wrote the manuscript. T.-R.W., Z.P., K.Z., X.L., and X.S. revised the manuscript.

Conflict of interest

The authors declare no conflict of interest.

Supplementary information

Supplementary file provided by the authors. Access here

The supporting materials are published as submitted, without typesetting or editing. The responsibility for scientific accuracy and content remains entirely with the authors.

References

- He J, Tritt TM. Advances in thermoelectric materials research: Looking back and moving forward. Science 2017; 357: eaak9997. [Article] [CrossRef] [PubMed] [Google Scholar]

- Zhu T, Liu Y, Fu C, et al. Compromise and synergy in high-efficiency thermoelectric materials. Adv Mater 2017; 29: 1605884. [Article] [CrossRef] [Google Scholar]

- Liu H, Shi X, Xu F, et al. Copper ion liquid-like thermoelectrics. Nat Mater 2012; 11: 422-425. [Article] [Google Scholar]

- Zhang Z, Zhao K, Chen H, et al. Entropy engineering induced exceptional thermoelectric and mechanical performances in Cu2-yAgyTe1-2xSxSex. Acta Mater 2022; 224: 117512. [Article] [Google Scholar]

- Poudel B, Hao Q, Ma Y, et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 2008; 320: 634-638. [Article] [CrossRef] [PubMed] [Google Scholar]

- Zheng Y, Zhang Q, Su X, et al. Mechanically robust BiSbTe alloys with superior thermoelectric performance: A case study of stable hierarchical nanostructured thermoelectric materials. Adv Energy Mater 2015; 5: 1401391. [Article] [CrossRef] [Google Scholar]

- Mao J, Zhu H, Ding Z, et al. High thermoelectric cooling performance of n-type Mg3Bi2-based materials. Science 2019; 365: 495-498. [Article] [Google Scholar]

- Zhao X, Yang S, Wen X, et al. A fully flexible intelligent thermal touch panel based on intrinsically plastic Ag2S semiconductor. Adv Mater 2022; 34: 2107479. [Article] [CrossRef] [Google Scholar]

- Yang Q, Yang S, Qiu P, et al. Flexible thermoelectrics based on ductile semiconductors. Science 2022; 377: 854-858. [Article] [NASA ADS] [CrossRef] [PubMed] [Google Scholar]

- Wei T, Qiu P, Zhao K, et al. Ag2Q-Based (Q = S, Se, Te) silver chalcogenide thermoelectric materials. Adv Mater 2023; 35: 2110236. [Article] [CrossRef] [PubMed] [Google Scholar]

- Ma Y, Huang H, Liu Y, et al. Remarkable plasticity and softness of polymorphic InSe van der Waals crystals. J Materiomics 2023; 9: 709-716. [Article] [Google Scholar]

- Qin H, Qu W, Zhang Y, et al. Nanotwins strengthening high thermoelectric performance bismuth antimony telluride alloys. Adv Sci 2022; 9: 2200432. [Article] [CrossRef] [Google Scholar]

- Zhu Y, Sun Y, Zhu J, et al. Mediating point defects endows n-Type Bi2Te3 with high thermoelectric performance and superior mechanical robustness for power generation application. Small 2022; 18: 2201352. [Article] [CrossRef] [PubMed] [Google Scholar]

- Wang W, Sun Y, Feng Y, et al. High thermoelectric performance bismuth telluride prepared by cold pressing and annealing facilitating large scale application. Mater Today Phys 2021; 21: 100522. [Article] [Google Scholar]

- Chen H, Wei T, Zhao K, et al. Room-temperature plastic inorganic semiconductors for flexible and deformable electronics. InfoMat 2021; 3: 22-35. [Article] [Google Scholar]

- Qiu J, Yan Y, Luo T, et al. 3D Printing of highly textured bulk thermoelectric materials: Mechanically robust BiSbTe alloys with superior performance. Energy Environ Sci 2019; 12: 3106-3117. [Article] [Google Scholar]

- Qiu J, Yan Y, Xie H, et al. Achieving superior performance in thermoelectric Bi0.4Sb1.6Te3.72 by enhancing texture and inducing high-density line defects. Sci China Mater 2021; 64: 1507-1520. [Article] [Google Scholar]

- Sun Y, Guo F, Feng Y, et al. Performance boost for bismuth telluride thermoelectric generator via barrier layer based on low Young’s modulus and particle sliding. Nat Commun 2023; 14: 8085. [Article] [Google Scholar]

- Zhu Y, Jin Y, Zhu J, et al. Design of n-type textured Bi2Te3 with robust mechanical properties for thermoelectric micro-refrigeration application. Adv Sci 2023; 10: 2206395. [Article] [CrossRef] [Google Scholar]

- Ferhat M, Nagao J. Thermoelectric and transport properties of β-Ag2Se compounds. J Appl Phys 2000; 88: 813-816. [Article] [Google Scholar]

- Mi W, Qiu P, Zhang T, et al. Thermoelectric transport of Se-rich Ag2Se in normal phases and phase transitions. Appl Phys Lett 2014; 104: 133903. [Article] [CrossRef] [Google Scholar]

- Huang S, Wei TR, Chen H, et al. Thermoelectric Ag2Se: Imperfection, homogeneity, and reproducibility. ACS Appl Mater Interfaces 2021; 13: 60192-60199. [Article] [Google Scholar]

- Wang H, Feng X, Lu Z, et al. Synergetic enhancement of strength-ductility and thermoelectric properties of Ag2Te by domain boundaries. Adv Mater 2023; 35: 2302969. [Article] [CrossRef] [Google Scholar]

- Peng L, Yang S, Wei TR, et al. Phase-modulated mechanical and thermoelectric properties of Ag2S1-xTex ductile semiconductors. J Materiomics 2022; 8: 656-661. [Article] [Google Scholar]

- Huang H, Chen H, Gao Z, et al. Room-temperature wide-gap inorganic materials with excellent plasticity. Adv Funct Mater 2023; 33: 2306042. [Article] [CrossRef] [Google Scholar]

- Feng L, Guo A, Liu K, et al. Highly deformable Ag2Te1-xSex-based thermoelectric compounds. Mater Today Phys 2023; 33: 101051. [Article] [Google Scholar]

- Chen J, Sun Q, Bao D, et al. Simultaneously enhanced strength and plasticity of Ag2Se-based thermoelectric materials endowed by nano-twinned CuAgSe secondary phase. Acta Mater 2021; 220: 117335. [Article] [Google Scholar]

- Wang H, Liu X, Zhou Z, et al. Constructing n-type Ag2Se/CNTs composites toward synergistically enhanced thermoelectric and mechanical performance. Acta Mater 2022; 223: 117502. [Article] [Google Scholar]

- Liang J, Qiu P, Zhu Y, et al. Crystalline structure-dependent mechanical and thermoelectric performance in Ag2Se1–xSx system. Research 2020; 2020: 6591981 [Google Scholar]

- Liu Z, Gao W, Meng X, et al. Mechanical properties of nanostructured thermoelectric materials α-MgAgSb. Scripta Mater 2017; 127: 72-75. [Article] [Google Scholar]

- Shu R, Zhou Y, Wang Q, et al. Mg3+δSbxBi2−x family: A promising substitute for the state-of-the-art n-type thermoelectric materials near room temperature. Adv Funct Mater 2019; 29: 1807235. [Article] [CrossRef] [MathSciNet] [Google Scholar]

- Zhu T, Su X, Zhang Q, et al. Structural transformation and thermoelectric performance in Ag2Te1−xSex solid solution. J Alloys Compd 2021; 871: 159507. [Article] [Google Scholar]

- Liu M, Zhang X, Zhang S, et al. Ag2Se as a tougher alternative to n-type Bi2Te3 thermoelectrics. Nat Commun 2024; 15: 6580. [Article] [Google Scholar]

- Li G, Aydemir U, Duan B, et al. Micro- and macromechanical properties of thermoelectric lead chalcogenides. ACS Appl Mater Interfaces 2017; 9: 40488-40496. [Article] [Google Scholar]

- Li A, Wang Y, Li Y, et al. High performance magnesium-based plastic semiconductors for flexible thermoelectrics. Nat Commun 2024; 15: 5108. [Article] [Google Scholar]

- Isotta E, Peng W, Balodhi A, et al. Elastic moduli: A tool for understanding chemical bonding and thermal transport in thermoelectric materials. Angew Chem Int Ed 2023; 62: e202213649. [Article] [CrossRef] [PubMed] [Google Scholar]

- Agne M T, Imasato K, Anand S, et al. Heat capacity of Mg3Sb2, Mg3Bi2, and their alloys at high temperature. Mater Today Phys 2018; 6: 83-88. [Article] [Google Scholar]

- Jiang J, Britton TB, Wilkinson A J. Evolution of dislocation density distributions in copper during tensile deformation. Acta Mater 2013; 61: 7227-7239. [Article] [Google Scholar]

- Bacon DJ, Hull D. Introduction to Dislocations. Amsterdam: Elsevier, 2011 [Google Scholar]

- Zhang BB, Yan FK, Zhao MJ, et al. Combined strengthening from nanotwins and nanoprecipitates in an iron-based superalloy. Acta Mater 2018; 151: 310-320. [Article] [Google Scholar]

- Li D, Zhang JH, Li JM, et al. High thermoelectric performance for an Ag2Se-based material prepared by a wet chemical method. Mater Chem Front 2020; 4: 875-880. [Article] [Google Scholar]

- Yang D, Su X, Meng F, et al. Facile room temperature solventless synthesis of high thermoelectric performance Ag2 Se via a dissociative adsorption reaction. J Mater Chem A 2017; 5: 23243-23251. [Article] [Google Scholar]

- Liang J, Liu J, Qiu P, et al. Modulation of the morphotropic phase boundary for high-performance ductile thermoelectric materials. Nat Commun 2023; 14: 8442. [Article] [Google Scholar]

- Liu W, Zhang Q, Lan Y, et al. Thermoelectric property studies on Cu-doped n-type CuxBi2Te2.7Se0.3 nanocomposites. Adv Energy Mater 2011; 1: 577-587. [Article] [Google Scholar]

- Hong M, Wang Y, Liu W, et al. Arrays of planar vacancies in superior thermoelectric Ge1−x−yCdxBiyTe with band convergence. Adv Energy Mater 2018; 8: 1801837. [Article] [CrossRef] [Google Scholar]

- Chen H, Shao C, Huang S, et al. High-entropy cubic pseudo-ternary Ag2(S, Se, Te) materials with excellent ductility and thermoelectric performance. Adv Energy Mater 2024; 14: 2303473. [Article] [CrossRef] [Google Scholar]

- Wang H, Pei Y, LaLonde AD, et al. Weak electron-phonon coupling contributing to high thermoelectric performance in n-type PbSe. Proc Natl Acad Sci USA 2012; 109: 9705-9709. [Article] [Google Scholar]

- Wei TR, Tan G, Wu CF, et al. Thermoelectric transport properties of polycrystalline SnSe alloyed with PbSe. Appl Phys Lett 2017; 110: 053901. [Article] [CrossRef] [Google Scholar]

- Yang S, Gao Z, Qiu P, et al. Ductile Ag20S7Te3 with excellent shape-conformability and high thermoelectric performance. Adv Mater 2021; 33: 2007681. [Article] [CrossRef] [PubMed] [Google Scholar]

All Figures

|

Figure 1 (A) Average values of the compression strength and ultimate strain for Ag2Se1–xTex samples in this work (red stars); data of Ag2Se [27,28,33], Ag2Te [23,26], Ag2Te1–ySey [26] and Bi2Te3-based polycrystalline thermoelectric materials [6,12–14,17–19] are included for comparison. Raw data are listed in Table S1. (B) Comparison of mechanical and physical properties between Ag2Se0.9Te0.1 and typical Bi2Te3-based polycrystalline thermoelectric materials [6,12]. |

| In the text | |

|

Figure 2 (A) Compression strength, compression strain and bending strength for Ag2Se1–xTex samples. (B) Fracture toughness KIC for Ag2Se1–xTex samples; data of Bi0.5Sb1.5Te3 [6], Mg3Sb1.3Bi0.7 [31], PbTe [34] are also given for comparison. (C) Schematic illustration of energy absorption (modulus of toughness) for Ag2Se under compression test. (D) Modulus of toughness for Ag2Se, Ag2Se0.9Te0.1 and other typical thermoelectric materials [12,30,35]. The error bars in panels A, B, and D denote the standard deviation from multiple measurements. |

| In the text | |

|

Figure 3 Transmission electron microscope (TEM) analysis of Ag2Se0.9Te0.1 sample with a compression strain 10%. (A) Bright-field image showing typical dislocations marked by red arrows. (B) HRTEM image and corresponding FFT image highlighting the dislocation array. (C) HRTEM image illustrating two sub-grains; inset images are FFT images. (D) Grain interface of the red area in Panel (C); two sets of planes are marked as red and yellow dots, respectively. |

| In the text | |

|

Figure 4 (A) Absolute Seebeck coefficient |S| versus carrier concentration nH for Ag2Se1–xTex materials at 300 K. Data of other Ag2Se-based materials are taken from Refs. [29,43]. The dashed line represents the calculated Pisarenko curve by the SPB model. (B) Relations of weighted mobility and lattice thermal conductivity with Te content; the dashed lines are calculated curves. (C) Temperature dependence of zT value for Ag2Se1–xTex samples with optimized Ag content. (D) zT value versus carrier concentration nH for Ag2Se1–xTex materials at 300 K. Data of other Ag2Se-based materials are taken from Refs. [29,43]. The dashed line represents the calculated Pisarenko curve by the SPB model. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.