| Issue |

Natl Sci Open

Volume 4, Number 2, 2025

Special Topic: Flexible Electronics and Micro/Nanomanufacturing

|

|

|---|---|---|

| Article Number | 20240044 | |

| Number of page(s) | 48 | |

| Section | Engineering | |

| DOI | https://doi.org/10.1360/nso/20240044 | |

| Published online | 30 October 2024 | |

REVIEW

The state-of-the-art fundamentals and applications of micro-energy systems on-chip

1

Ministry of Education Key Laboratory of Micro/Nano Systems for Aerospace, Key Laboratory of Micro- and Nano-Electro-Mechanical Systems of Shaanxi Province, School of Mechanical Engineering, Northwestern Polytechnical University, Xi’an 710072, China

2

Qinghai Huanghe Hydropower Development Co., Ltd., Xi'an Solar Power Branch, Xi'an 710100, China

3

Centre for Nanofibers and Nanotechnology, Department of Mechanical Engineering, National University of Singapore, Singapore 117576, Singapore

* Corresponding author (email: This email address is being protected from spambots. You need JavaScript enabled to view it.

)

Received:

24

August

2024

Revised:

21

September

2024

Accepted:

29

October

2024

Abstract

In the past decade, micro-energy systems on-chip (MESOC) have been widely studied from energy collection to storage, management, and system integration, their applications have been explored in fields such as low-power and self-powered microelectronic devices (sensors, actuators, modulators, etc.). These applications fundamentally require an efficient, stable, and highly integrated power platform to meet specific energy demands. Traditional energy solutions rely heavily on external power supplies or periodic replacement of energy storage batteries. Although these approaches can provide stable power outputs, the large size and low energy density make it difficult to adapt to the miniaturization of electronic devices. Breakthroughs in the field of MESOC can significantly improve the portability and independence of advanced microelectronic devices by harvesting abundant environmental energy resources. In this work, we discuss new opportunities for MESOC, including newly investigated microscale energy harvesting devices, advanced energy storage devices, high-efficiency management modules, and system integration. Finally, future applications and prospects are discussed, aiming to promote a wider range of lightweight and efficient MESOC.

Key words: micro-energy systems / self-powering / system on chip / integration of micro-energy system

© The Author(s) 2024. Published by Science Press and EDP Sciences.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

INTRODUCTION

With the rapid development of the Internet of Things (IoT), wearable devices, and implantable medical devices, requirements for energy supply micro-equipment (devices) have significantly increased. This equipment should have the characteristics of high energy efficiency, miniaturization of size/weight, and high autonomy [1–4]. Micro-energy systems on-chip (MESOC) is an emerging energy supply micro-equipment, and it has been developed rapidly in recent years [5,6]. It integrates a variety of microscale energy collection/storage devices and energy management modules on a chip, realizing self-power supply and efficient energy management for microelectronic devices [7–9]. Traditional electronic systems often rely on external power supplies or periodic replacement of energy storage batteries. MESOC significantly reduces dependence on external power supplies by harvesting sufficient energy from the environment, such as light, vibration, and heat [10–12]. This technology provides an autonomous and sustainable energy supply solution for advanced microelectronic devices.

MESOC consists of three parts: energy harvesting devices, energy storage devices, and energy management modules, as shown in Figure 1. The energy harvesting part is the core of MESOC, which can convert various energies from the surrounding environment into electricity [13–16], such as mechanical energy, thermal energy, light energy [17–20]. For example, piezoelectric materials can convert mechanical energy into electricity, and thermoelectric materials can convert thermal energy into electricity through temperature difference [21,22]. These electrical energies provide the necessary energy supply for MESOC, also the energy collected by the energy harvesting device is irregular, energy storage devices are needed to store and release the energy with specific demands within the MESOC [23,24]. Meanwhile, the energy storage device can store excess energy and provide necessary supplements when the energy supply is insufficient to achieve a balance between supply and demand [25–27]. At present, the mainstream energy storage devices mainly include supercapacitors (SC) and energy storage batteries. SC has the characteristics of fast charging and discharging capacities and long service life [28–30]. Energy storage batteries have high energy density and long power supply capacity [23,31,32]. The existence of energy storage devices enables MESOC to cope with a wide power range of energy demands [33]. The energy management module is responsible for converting, regulating, and distributing energy to ensure efficient energy utilization and stable operation of the following microelectronic devices [34,35]. The energy management module can not only meet the energy needs of various micro devices, but also can be flexibly adjusted according to the needs of different application scenarios [36–38].

|

Figure 1 The structure of MESOC [53–61]. Copyright©2021, Springer Nature; Copyright©2021, Royal Society of Chemistry; Copyright©2021, American Chemical Society; Copyright©2023, American Chemical Society; Copyright©2014, IEEE; Copyright©2021, IOP Publishing; Copyright©2021, Royal Society of Chemistry; Copyright©2022, Elsevier; Copyright©2019, Elsevier, respectively. |

To achieve miniaturization of MESOC and improve autonomy, reliability, and energy utilization efficiency, material selection and preparation methods play an important role in MESOC. During the design and preparation processes, the physical properties, chemical stability, and manufacturing feasibility of the functional materials need to be comprehensively considered. The high-performance materials and optimized preparation methods can significantly improve the energy density, conductive performance, and stability of the chip, promoting its wide applications in the field of microelectronic devices [39–42]. The development of MESOC has brought a new solution to the energy supply of microelectronic devices, and is expected to be widely used in various portable and self-powered devices in the future [43–45]. However, the practical applications of MESOC still face challenges. The energy collection and conversion efficiency still need to be further improved to reduce energy waste, extend the power supply time, and improve the overall performance of the system [46–49]. Meanwhile, it is also difficult to achieve efficient integration of multiple functional modules in a limited space [32,50,51]. In addition, the reliability and durability of the system still need to be optimized to ensure stable operation under various environmental conditions [52]. Future research directions will focus on improving system integration, optimizing energy conversion efficiency, and enhancing system durability.

This work reviews the latest progress of MESOC and summarizes the material selection, manufacturing techniques, and integration methods of MESOC. It also summarizes the latest technologies and future development trends of MESOC in energy collection, storage, and energy management modules, providing technical support and innovation directions for the next generation of micro-energy autonomous devices. Finally, the potential advantages and challenges of MESOC in practical applications are discussed.

ENERGY HARVESTING DEVICE

MESOC have the advantages of efficient energy utilization, self-sustaining operation, environmental friendliness, compactness and portability, multiple functions, easy personalization, etc., providing key support for the development of advanced microelectronic devices [40,62]. Energy collectors play important roles in energy conversion, collection, stable power supply, and reduction of dependence on external power supplies in MESOC [63–65]. They are the key component to achieving the self-sustainable operation of microelectronic devices [66,67]. These energy-harvesting devices harness ambient energy sources, such as mechanical motion, light, and heat, and convert them into electricity to power autonomous devices without resorting to conventional batteries [15,68–70]. Energy collectors not only extend the life of the device but also minimize the impact on the environment by reducing battery waste [71].

In recent years, energy harvesters integrated into MESOC have been developed, and efforts have been made to combine them with other functional devices, allowing microdevices and sensor systems to operate without external batteries or power sources [55,72,73]. There are four primary types of energy harvesting components: thermal energy harvesters, piezoelectric energy harvesters, solar energy harvesters, and radio frequency energy harvesters. In this chapter, we summarize recent developments in various energy harvesters and their applications in MESOC.

Thermal energy harvesting

A thermoelectric generator (TEG) converts heat into electricity, functioning as an energy-harvesting device without requiring an external power source [41,74]. In addition, the TEG operates with temperature differences in quiet and closed environments [35,75]. At the same time, TEG can be connected in series or parallel to meet a wide range of power demands, enabling the adjustment of output power according to specific application needs [76–78].

The working principle of TEGs is primarily based on the Seebeck effect, which occurs when a temperature gradient occurs between two different materials. TEG typically consists of multiple thermoelectric couplers, each made of two different materials (e.g., copper and silver). These couplers are arranged together in the form of thermoelectric modules. There are two thermally conductive metal plates inside the thermoelectric module, which fix the coupler to the metal plates. These metal plates act as heat exchangers, transferring heat from the hot side to the cold side. TEG can be used to power electrical loads on an external circuit using waste heat flow across a temperature gradient [14,15]. By establishing a conductive connection between two types of materials (P and N), an electromotive force is established in a specific direction, forcing the flow of charges to produce an electric current, as shown in Figure 2a and b [54,79].

|

Figure 2 TEGs for energy harvesting in MESOC. (a) TE phenomenon in n-type and p-type materials and the working principle of thermoelectric devices [54]. Copyright©2021, Royal Society of Chemistry. (b) The schematic diagram of a TE module consists of p- and n-type legs [79]. Copyright©2020, Elsevier. (c) The voltage generated by the body temperature, by collecting the body temperature to power the LED [93]. Copyright©2023, Elsevier. (d) Pyroelectricity of lead sulfide quantum dot films induced by Janus-ligand shells [95]. Copyright©2021, American Chemical Society. (e) Schematic diagram of the complete heat transfer process of a wearable thermoelectric device [97]. Copyright©2021, Elsevier. (f) Novel wearable pyrothermoelectric hybrid generator for solar energy harvesting [98]. Copyright©2022, American Chemical Society. |

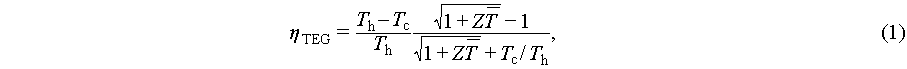

The materials used in TEG play a crucial role in their performance. A good thermoelectric material requires high electrical conductivity, high Seebeck coefficient, and low thermal conductivity, which enables it to efficiently convert thermal energy into electricity. The maximum power generation efficiency (ηTEG) of the thermoelectric generator is defined by Eq. (1) [80]:

(1)

(1)

where Th and Tc are the hot end and the cold end temperatures (K) of the thermoelectric module, respectively.  is the average temperature,

is the average temperature,  is the dimensionless figure of merit, which is related to the device material and the calculation formula is shown in Eq. (2):

is the dimensionless figure of merit, which is related to the device material and the calculation formula is shown in Eq. (2):

(2)

(2)

where α is the Seebeck coefficient (V K−1), σ is the electrical conductivity (S m−1), κ is the thermal conductivity which is separated into the carrier transport (κe) and lattice thermal conductivity (κL) (W mk−1), and α2σ is defined as the power factor [81].

The main thermoelectric materials used include Bi2Te3/Sb2Te3, SnSe single crystals, GeTe alloys, and Cu2Se. Through nanotechniques, such as grain refinement, doping, and pore design, the thermal conductivity of the material can be reduced without sacrificing electrical transport properties, thereby improving thermoelectric performance. High entropy alloys (such as alloys formed by mixing elements such as titanium, chromium, molybdenum, and iron) improve efficiency by reducing lattice thermal conductivity, and they are suitable for high-temperature environments. Organic-inorganic hybrid materials formed by combining organic conductive polymers with inorganic semiconductors (such as PbTe) not only reduce cost, but also improve the scalability and customizability of TEG. Phase change materials such as paraffin and fatty acid mixtures were used to maintain temperature differences and ensure the stability of energy output [82–86].

The preparation methods of TEG mainly involve the synthesis of thermoelectric materials and the design of module structures. Common preparation methods include hot pressing sintering, solution synthesis, and chemical vapor deposition (CVD). These methods aim to optimize the thermoelectric performance of materials by fine-controlling their microstructures. The design of thermoelectric modules needs to consider the shape and size of thermoelectric materials, the arrangement of thermocouples, and the contact interface with heat and cold sources. Optimizing the shape of thermoelectric legs and multi-level configuration can effectively utilize heat flow and increase output power. The assembly of modules usually adopts low-cost and high-reliability contact methods, such as nickel-gold (Ni-Au) contact materials, to improve the stability and reliability of the modules [87,88].

TEG has attracted wide attention due to its high integration, high energy collection efficiency, reliability, and flexibility. Researchers have improved the thermoelectric and mechanical properties by improving the material structure and process, achieved efficient energy conversion of TEGs under low-temperature differences, and verified the application potential of TEG in MESOC [89,90]. In 2012, Yang et al. [91] used zinc oxide (ZnO) nanowire arrays to create a thermoelectric nanogenerator. The coupling of pyroelectric and semiconducting properties in ZnO generated polarizing electric fields and charge separation along ZnO nanowires due to time-dependent changes in temperature. Experimental results showed that the fabricated nanogenerator showed good stability, and the characteristic coefficient of heat flow conversion current was about 0.05‒0.08 V m2 W−1. In 2019, K. Allison et al. [92] prepared an all-fiber TEG by vapor deposition of continuously p-doped poly(3,4-ethylenedioxythiophene) on commercial cotton fabric. The reactive vapor coating process enabled the preparation of mechanically stable fiber thermopiles with significantly high thermoelectric power factors. A high power factor of 0.48 μW m−1 K−2 at low-temperature differences was achieved for the TEG. Experiments have proven that this all-fiber thermopile could generate a thermal voltage of more than 20 mV when worn on the hand. In 2023, Zhu et al. [93] developed a self-healing and recyclable TEG to achieve energy harvesting and thermal management (Figure 2c). The TEG was prepared with dynamic covalent polyimide as the base material, highly conductive flowing liquid metal electrodes and N/P type thermoelectric legs. The device had excellent self-healing and recyclable properties due to dynamic covalent bonds in the polyimide substrate. Due to low internal impedance and excellent heat dissipation design, the device enabled flexible thermal regulation and a high cooling effect. This TEG has achieved a power density of 1.54 μW cm−2 K−2 to provide a record 13.8°C body cooling effect with a high-performance factor of 3.91 at a temperature difference of 7°C, indicating low power consumption for human body cooling. This research successfully developed a thermoelectric device with flexibility, self-healing, recyclability, high cooling effect, and high power density, providing new development opportunities in the fields of wearable energy collection and personal thermal management. In the same year, Kong et al. [94] reported a tellurium nanowire-doped thermoelectric hydrogel with high stretchability and high Seebeck coefficient for low-level thermal energy conversion. The optimized hydrogel composite showed a Seebeck coefficient as high as 787 μV K−1, thermal conductivity as low as 0.468 W m−1 K−1, and tensile strain as high as approximately 400%. A wearable electromechanical module with a staggered Z-shaped structure was developed to achieve a voltage output of 138 mV when applied to a human arm. After being integrated with the power management module, the operation of powering electronic devices, such as commercial calculators and white light-emitting diode (LED), was realized. It exhibited great application potential in the fields of human body heat energy harvesting and wearable electronics. In 2021, Huang et al. [95] developed a method to generate Janus ligand shells on symmetric PbS quantum dots (Figure 2d). Two different configurations were presented, in which pyroelectric currents can be observed, one in which the quantum dots were self-assembled into a closely packed array and one in which the quantum dots were dispersed into the non-electroactive polymer polydimethylsiloxane. The experimental results showed that the thermoelectric coefficients calculated for the two configurations were 1.97 × 10−7 and 2.07 × 10−15 C m−2 K−1, respectively. The thermoelectric effect of Janus quantum dot films assembled under a strong electric field was enhanced. Compared with self-assembled quantum dots under 20 V conditions, the thermal current increased approximately three times. In 2023, Wei et al. [96] prepared graphite nanoribbon (GNR) through a chemical unbundling method and fabricated a GNR-based TEG on a polytetrafluoroethylene (PTFE) film. Experimental results showed that GNR TEG had a high Seebeck coefficient of 68 μV K−1 and power factor of 6.76 μW m−1 K−2, which were significantly higher than previous graphite-based TEG. In addition, tests showed that GNR TEG had good mechanical robustness and flexibility (After 1000 bending tests, its conductivity, Seebeck coefficient, and power factor showed no change). In 2021, Lv et al. [97] prepared a flexible spring-shaped thermoelectric energy harvester with an optimized thermal design (Figure 2e). By using vertical temperature gradients, the researchers successfully leveraged traditional thermoelectric carbon nanotube (CNT) films to achieve efficient thermal energy utilization through a three-dimensional (3D) spring-shaped device architecture. This rationally designed device had double elastic connection layers and a middle air gap, which not only improved the heat utilization efficiency, but also showed excellent flexibility and compressibility. The TEG produced an output power of 749.19 nW under a vertical temperature gradient of 30 K by using only 3 pairs of the P-N couplings. This design provides a new application direction for traditional thermoelectric films and promotes the effective utilization of vertical temperature gradients, which will benefit the development of TEG in MESOC. In 2022, Zhang et al. [98] proposed a novel wearable solar-thermoelectric hybrid generator that effectively used solar energy as a heat source (Figure 2f). Efficient CNT/carbon ribbon (CT) solar absorbers were developed to fully utilize solar energy as a heat source. This new type of generator enabled efficient energy harvesting from dynamic temperature fluctuations and static temperature gradients. The entire device was assembled from films and yarns, making the developed thermoelectric hybrid generator light-weight and flexible. Under an illumination intensity of 1500 W m−2 (1.5 sun), the generator successfully charged two commercial capacitors with a sum voltage of 3.7 V, the total energy could illuminate 73 LEDs. In 2024, Li et al. [99] used interstitial Cu and thermal deformation processes to optimize the thermoelectric properties of BiTeSe and prepared high-performance thermoelectric modules based on this material. The research team demonstrated that interstitial Cu reduced the defect density in the matrix and suppressed the donor-like effect, resulting in a lattice flattening effect. In addition, the two-step thermal deformation process significantly improved the preferred orientation of the crystal and increased the mobility of the charge carrier. The fabricated TEG module achieved an impressive conversion efficiency of 6.5% at the temperature difference of 225 K.

In 2022, Xiao et al. [100] prepared a TEG and applied it to a self-powered wireless bluetooth (BLE) sensing system. Under a temperature difference of 52°C, the output voltage reached 1.3 V, and the maximum output power and power density were 95.9 mW and 610.8 μW cm−2, respectively. The research team integrated TEG with a bluetooth sensing system that could detect environmental parameters (such as temperature and humidity) with low power consumption and transmit data to smartphones or other devices via bluetooth. In 2023, Fan et al. [101] reported a highly efficient TEG that could simultaneously achieve comfortable wearability and excellent output performance. The TEG could efficiently power commercial light-emitting diodes and stably drive the ECG module in real-time without the help of any additional power supply. In the same year, Cho et al. [102] used the motor functional layered structure, conductive silver nanowire-based electrodes and an improved thermal interface to significantly improve the performance of TEG. The research team integrated the TEG into a life jacket and powered a bluetooth tracker by harvesting body heat. TEG energy was enough to drive circuits and equipment in the rescue system, including wireless signal transmission modules and LED lights that displayed “SOS” signals. In 2024, van Toan et al. [103] proposed an N-type flexible composite material based on single-walled carbon nanotubes (SWCNTs) and doped with sodium hydroxide (NaOH). The TEG was integrated with a sensor to assemble a self-powered temperature and strain sensor. The sensor could effectively monitor temperature changes (temperature resolution up to 0.12 K) and strain deformation (strain response time of 0.7 s) through thermoelectric power generation technology without the need for any external power supply.

Table 1 lists the results of some of the most recent studies on TEG. The above research work has made significant progress in the field of TEG, especially in thermoelectric material performance optimization and system structure design. However, current TEG still faces some shortcomings and challenges. At present, the thermoelectric performance (ZT value) of thermoelectric conversion materials is still low, especially under normal temperature conditions. The ZT values of many thermoelectric materials are usually around 1, indicating relatively low energy conversion efficiency. As the temperature difference decreases, the thermoelectric conversion efficiency further decreases, resulting in the limitation of the practicality of thermal energy harvesting devices in low-temperature difference environments. Thermoelectric materials are easily affected by environmental conditions, such as temperature fluctuations and humidity changes during long-term operation. These external factors may cause degradation of the performance of the thermoelectric (TE) material, thereby reducing the reliability of the system. To integrate TEG into the MESOC system, it is necessary to solve the compatibility problem of the TEGs with other functional modules. Optimizing the contact interface between the thermoelectric materials and other materials is a potential method to reduce the interface thermal resistance and further improve the energy conversion efficiency of the overall system. Nonetheless, these challenges also provide opportunities for future research and technological innovation, including developing new efficient thermoelectric materials, optimizing thermoelectric device structures, and improving energy storage and management strategies, thereby promoting the development and application of TEG-based MESOC.

The materials, preparation method, thickness, VOC and power generated by TEG reported in recent literatures

Piezoelectric energy

Piezoelectric nanogenerator (PENG) plays an important role in MESOC due to their advantages of miniaturization, efficient energy harvesting, environmental adaptability, and low-cost preparation [104,105]. PENG can utilize tiny mechanical vibrations or motions of piezoelectric structures to convert mechanical energy into electricity, and the principle of PENG is shown in Figure 3a [106]. This energy harvesting method is a renewable energy option that does not require external power input. The miniaturization and flexibility of PENG allow it to be fabricated as a miniature device that can be integrated with other miniature energy harvesting devices, energy storage devices, and energy management modules to form a complete MESOC [107,108]. This miniaturized and integrated design can greatly reduce the system size/weight and improve the integration and stability of the system. Meanwhile, the PENG can adapt to various environmental conditions and work under different vibration frequencies and amplitudes. Since PENG can be made of flexible piezoelectric films, the on-chip-for-energy system can be applied to non-planar and dynamic human surfaces to generate energy from human daily activities (i.e., walking, bending joints, and even blood vessel pulsations) [109–111]. Therefore, the MESOC can be applied in a variety of environments, including indoor and outdoor activities, to provide a stable power supply for various microelectronic devices.

|

Figure 3 PENGs for energy harvesting in MESOC. (a) The principle of PENG generating electricity. Reproduced from permission [55]. Copyright©2021, American Chemical Society. (b) Through constant tapping, the piezoelectric generator lights up ten LEDs. Reproduced from permission [127]. Copyright©2021, Elsevier. (c) FPNG based on PVDF nanocomposite membranes. Reproduced from permission [128]. Copyright©2020, Elsevier. (d) Green composite from pomegranate peel for piezoelectric energy harvesting. Reproduced from permission [129]. Copyright©2019, American Chemical Society. (e) The piezoelectric output voltage of the PSNO film during external periodic vertical compression was obtained by pressing the PENG with a finger. Reproduced from permission [130]. Copyright©2018, American Chemical Society. (f) Voltage Generation by Finger Tapping in Nanocomposite Devices. Reproduced from permission [131]. Copyright©2018, American Chemical Society. (g) A flexible WCSPS for non-invasive measurement of pulse wave and blood pressure. Reproduced from permission [133]. Copyright©2019, Wiley. (h) Digital photographic image of the LCD switched on by the PENG device through a commercial capacitor of 4.7 μF and a bridge rectifier. Reproduced from permission [134]. Copyright©2021, American Chemical Society. |

The operating principle of PENG is based on the piezoelectric effect of specific materials. The equation that explains the piezoelectric phenomenon is shown in Eqs. (3) and (4) [112,113]:

(3)

(3)

(4)

(4)

where E is the electric field, D is electric displacement, ε is the permittivity of the material, d is the piezoelectric constant, s is mechanical compliance, T is stress, and X is strain.

The materials of PENG are divided into piezoelectric materials and electrode materials [114,115]. Currently, the mainstream piezoelectric materials include ZnO, lead zirconate titanate (PZT), BaTiO3, and polyvinylidene fluoride (PVDF). The piezoelectric properties of the same piezoelectric materials with different microstructures vary greatly. In recent years, significant progress has been made on new materials for piezoelectric generators. By combining the traditional piezoelectric material barium titanate with polymer materials to form piezoelectric nanocomposites, this strategy not only improved the piezoelectric performance, but also enhanced the durability of the material. Through the development of nanofibers and the controlling of microstructure, researchers have greatly optimized the piezoelectric constant and mechanical strength of the material [116–118]. Electrode materials mainly include metals, electroplated fabrics, conductive polymers, carbon-based additives, and mixed particles. Metal electrodes, such as gold and aluminum, have high conductivity. Conductive polymers include polypyrrole and polyaniline. Carbon-based additives include graphene and CNT [119,120].

The preparation methods of PENG include solution casting, electrospinning, and in-situ growth. Solution casting is a commonly used method for preparing piezoelectric films. By controlling the solvent type and temperature, a high-β phase PVDF film can be obtained. Electrospinning combines electric polarization and mechanical stretching to prepare nanofiber membranes with large piezoelectric coefficients. There are two types of electrospinning: far-field electrospinning (FFES) and near-field electrospinning (NFES). The nanofibers generated by FFES are random, while NFES can produce ordered nanofibers. The in-situ growth method is used to grow ZnO nanomaterials on flexible substrates, and ZnO nanowires and nanorods are grown on conductive fabrics by a chemical hydrothermal method to prepare efficient PENG. In addition, there is a solution blow spinning method, which has the advantages of high production efficiency, easy implementation, and the ability to deposit fibers onto any collector without high voltage [121–123].

PENG has attracted extensive attention due to its ability to harvest energy from ordinary motion in MESOC [124–126]. In 2020, Mondal et al. [127] reported an interactive mechanical energy harvester for human movement based on a hybrid material of all-inorganic calcium lead bromide (CsPbBr3) and PVDF. By combining CsPbBr3 with PVDF at room temperature, the optimized composite with high-β phase content (>90%) was prepared. This composite material could generate energy in response to different types of external stimuli. After 15,000 cycles of bending tests in 4 months, the output performance of the prepared nanogenerator (PNG) did not degrade significantly, indicating its high stability and durability. The power generated by the as-prepared PENG under the action of periodic compression and release of stress was enough to light up 10 LEDs without any energy storage device (Figure 3b). In the same year, Bairagi et al. [128] reported a potassium sodium niobate (KNN) nanorods@poly(vinylidene fluoride) nanocomposite film-based flexible PENG. By changing the percentage of PVDF matrix in the KNN nanorods, the direct impact on the energy harvesting efficiency was observed. Experimental results showed that the flexible nanogenerator containing 10% KNN nanorods showed the highest performance in terms of output voltage, which benefited from the enhanced orientation of polarization moments in the PVDF polymer. The non-polarized 10% KNN nanorods@PVDF composite membrane was capable of generating an open circuit voltage of 3.4 V and a current of 0.100 μA by applying repeated compressive forces to it. The current density of the developed nanogenerator was 0.025 μA cm−2 (Figure 3c). Gaur et al. [129] used green composite materials exfoliated from biowaste colloids for piezoelectric energy collection and applied hybrid materials of PVDF and pomegranate peel waste to enhance piezoelectric energy collection (Figure 3d). The open circuit voltage and power density of the prepared PENG increased with the increase of pomegranate peel waste content. The open circuit voltage of 65 V and power density of 84 μW cm−2 were obtained for the hybrid device. This high-power density was mainly attributed to the synergistic effect between the piezoelectric pomegranate peel and the induced piezoelectric phase of the PVDF matrix. In addition, the PENG could also generate electricity under different types of human movements in daily activities (walking, twisting, bending, etc.). In 2018, Dutta et al. [130] proposed a new, flexible and high-performance PENG and tactile electronic skin mechanical sensor based on self-polarized NiO@SiO2/PVDF nanocomposite. Under the action of biomechanical force, the prepared PNG composed of nanocomposite materials showed good outputs. Its maximum output voltage was approximately 53 V, current density was approximately 0.3 μA cm−2, and instantaneous power density was approximately 685 W m−3. By gently pressing the nanogenerator with a human finger, 85 LEDs could be lighted up, as shown in Figure 3e. In the same year, Singh et al. [131] prepared a flexible and robust piezoelectric energy harvester based on MgO/P(VDF-TrFE) nanocomposite. The best piezoelectric properties were obtained by adding 2 wt% MgO into P(VDF-TrFE), and the piezoelectric coefficient increased by nearly 50% as compared to the plain P(VDF-TrFE) sample (Figure 3f). This was attributed to the preferential conformation of the P(VDF-TrFE) chains, the improved crystallinity of the P(VDF-TrFE) matrix, and the uniform distribution of the nanoparticles. The as-prepared PENG had superior energy harvesting performance and its output voltage (2 V) was increased. In addition to excellent electrical properties, this PENG also exhibited excellent durability against electrical and mechanical fatigues, with the piezoelectric coefficient remaining even after 10,000 bending cycles. In 2024, Peng et al. [132] integrated single-crystalline BaTiO3 (BTO) films between PVDF-trifluoroethylene copolymer (PVDF-TrFE) layers to prepare a new multilayer composite PENG. The PVDF-TrFE/BTO/PVDF-TrFE PENG exhibited significantly improved energy harvesting performance, with an output of up to 15.1 V, 2.39 μA, and a power density of 17.33 μW cm−2 during bending deformation.

In 2019, Meng et al. [133] proposed a weaving-constructed self-powered pressure sensor (WCSPS). The sensor used rational woven structure design and plasma etching to create surface polymer nanowires that could convert small blood pressure changes into electrical signals. WCSPS had an ultra-fast response time of less than 5 ms and an excellent sensitivity of 45.7 mV Pa−1. After 40,000 cycles of continuous operation, no performance degradation of the WCSPS was observed. In addition, in order to achieve a sensor system that was cost-effective, comfortable to wear, easy to use and have low power consumption, the research team also developed a sensor system including WCSPS, signal management circuit, and wireless transmission, which can transmit the measured cardiovascular parameters to personal mobile devices (Figure 3g). By optimizing at the system level, all system components could work together to enable continuous and non-invasive human health assessment and monitoring. In 2021, Manchi et al. [134] synthesized a ferroelectric material, lithium tantalate (LiTaO3), and used it to fabricate a flexible piezoelectric nanogenerator (FPNG). The ferroelectric material had a strong electrostatic dipole moment and a high piezoelectric coefficient, resulting in improved electrical properties. The effect of loaded LiTaO3 concentration on the electrical properties of FPNG was systematically investigated. The open-circuit voltage, short-circuit current, and power density values of 2.5 wt% FPNG were ~18 V, ~1.2 μA, and ~25 mW m−2, respectively. The FPNG was operated with a constant applied 4 N force and 5 Hz frequency, and the commercial liquid crystal display (LCD) could be illuminated by connecting capacitors through a bridge rectifier (Figure 3h).

Table 2 lists some recent results of the PENGs. Previous research works have made significant progress in PENG, but there are also some shortcomings. The energy output of existing PENGs is usually low, especially in small environmental vibrations or low-frequency mechanical movement conditions, which makes it difficult to provide sufficient energy to supply microelectronic devices. Although the piezoelectric coefficient can be improved by optimizing the material, it often leads to decreased mechanical properties and material stability. At the same time, there are large differences in vibration frequency and amplitude in different environments. Thus, it is a challenge to design a PENG that can adapt to a variety of environmental conditions. The current opportunity lies in the introduction of new materials and new fabrication processes, which are expected to significantly improve the performance of PENG and enable the integration and application of PENGs in MESOC.

The materials, preparation method, thickness, open-circuit voltage and short-circuit current of PENGs reported in the literatures

Solar cells

Solar cells can convert sunlight energy directly into electricity, playing a key role in providing a continuous, clean, and efficient energy supply. Converting sunlight directly into electrical energy through the photovoltaic effect is an ideal choice for MESOC energy harvesting devices. At the same time, solar cells are lightweight and can be integrated on chip, making MESOC more compact and portable [135–138].

The typical solar cell consists of a light-absorbing layer (P-N junction), electrodes, and an anti-reflection layer. The light-absorbing layer is usually made of semiconductor materials such as silicon, which is used to absorb sunlight and generate electron-hole pairs. The P-type and N-type regions are formed by doping N or P elements to form a P-N junction (Figure 4a) [139]. The electrode is used to collect charge carriers and transmit current. The anti-reflection layer covers the surface of the cell to reduce light reflection and improve light absorption efficiency, increasing the output current [140–144].

|

Figure 4 Solar cells for MESOC energy harvesting. (a) The principle of solar cell power generation [139]. Copyright©2023, Royal Society of Chemistry. (b) Silicon heterojunction solar cell [156]. Copyright©2024, Elsevier. (c) Schematic diagram of nano/micro hybrid structure array solar cell [157]. Copyright©2022, Royal Society of Chemistry. (d) Schematic diagram of the working principle of perovskite/silicon-based tandem solar cells [56]. Copyright©2023, American Chemical Society. (e) Schematic diagram of the structure of a PVK/Si tandem cell [173]. Copyright©2024, Wiley. (f) Self-powered smart bracelet [174]. Copyright©2021, American Chemical Society. (g) Schematic diagram of the Sb2Se3 micromodule and the flower monitor [175]. Copyright©2021, Elsevier. |

Solar cells are mainly composed of semiconductor materials that can absorb sunlight and convert it into electricity. Currently, commonly used solar cell materials include silicon (single-crystal silicon, polycrystalline silicon, and amorphous silicon), III–V compounds (such as gallium arsenide), II–VI compounds (such as cadmium sulfide and cadmium telluride), organic polymers, and organic-inorganic hybrid semiconductors. Silicon materials are the most commonly used photovoltaic materials because of their relatively high efficiency and low cost. New materials such as organic-inorganic hybrid perovskite materials have become a hot topic of research in recent years due to their excellent light absorption ability, high carrier mobility and adjustable band gap, and have the potential advantages of high efficiency and low cost [145–148].

The preparation methods of solar cells mainly include physical vapor deposition (PVD), CVD, solution processing, and spin coating. PVD methods such as electron beam evaporation and sputtering are often used to prepare high-quality thin films. CVD methods include thermal CVD and plasma-enhanced CVD, which are suitable for preparing large-area uniform thin film layers. The solution processing method dissolves the precursor material in a solvent and then forms a thin film by coating or spraying. It has the advantages of low cost and simple operation. The spin coating method is to evenly distribute the solution and form a thin film by rotating the substrate at high speed. It is often used to prepare organic and perovskite solar cells [149–152].

Solar cells are an ideal choice for MESOC energy collection devices due to their high efficiency, cleanliness, and noiselessness [153–155]. Ru et al. [156] achieved 26.6% efficiency on commercial-size P-type silicon wafers by using silicon heterojunction technology, as shown in Figure 4b. The carrier lifetime of P-type silicon wafers was improved by phosphorus diffusion and impurity removal. Nanocrystalline silicon was developed as a carrier selective contact layer, which significantly improved the cell efficiency. In 2022, Zhang et al. [157] introduced a simple and stable method to manufacture wafer-level ultra-black silicon, improving the performance of solar cells with 3D nano/micro hybrid structures. The “one-step metal-assisted chemical etching” method was proposed to form nano- and microstructures by ion beam bombardment (Figure 4c). The proposed fabrication method avoided the complex processes of traditional multiple photolithography and etching. Compared with traditional single microcolumn arrays, the efficiency of solar cells based on hybrid structures was improved by about 11.4%, demonstrating its potential for application in high-performance photovoltaic devices.

Apart from silicon solar cells, perovskite solar cells and organic solar cells have been comprehensively investigated by now. Perovskite materials have attracted much attention in recent years due to their unique optoelectronic properties and have shown great potential in the manufacture of solar cells. In 2021, Ye et al. [158] introduced phthalimide (PTM) to control the local electron density to stabilize B-γ CsSnI3-based perovskite solar cells. The study found that the –NH and two –CO functional groups in the PTM formed triangular coordination bonds with Sn2+, thereby inhibiting the oxidation of Sn2+ in the ambient air condition, reducing the defect density of the CsSnI3 film and increasing the grain order. The improved rigid and flexible B-γ CsSnI3-based solar cells achieved maximum efficiencies of 10.1% and 9.6%, respectively, and demonstrated excellent stability under inert gas, ambient air and continuous light conditions. In 2024, Jiang et al. [159] designed and synthesized a new asymmetric non-fullerene acceptor (Z8), and successfully improved the efficiency of organic solar cells to 20.2% through molecular design and device engineering. The design of Z8 optimized photovoltaic performance by reducing non-radiative energy loss and charge carrier recombination, and formed an alloy acceptor with another acceptor (L8-BO), which improved the nanomorphology of the film. Ding et al. [160] proposed a doping-additive synergistic enhancement strategy for perovskite solar cells. By combining methylammonium chloride (MACl) as the dopant and Lewis alkaline ionic liquid additive 1,3-bis(cyanomethyl) imidazolium chloride, the degradation of the perovskite precursor solution and the aggregation of MACl were effectively inhibited, and finally, a perovskite film with high crystallinity and fewer defects was obtained. The perovskite solar module prepared using this strategy achieved the certified efficiency of 23.30% at the aperture area of 27.22 cm2, and maintained the initial efficiency of 94.66% under 1000 h of continuous daylight illumination. Gong et al. [161] prepared a new type of perovskite hot carrier solar cell, which achieved an efficiency of more than 27% via fast hot hole transfer and using phthalocyanine derivatives as hole transport layers. The study used phthalocyanine-based materials to construct a hot hole collection layer, achieved the hole extraction rate of up to 78,900 cm s−1 through methylthiotriphenylamine phthalocyanine, and achieved a single-junction perovskite solar cell with an efficiency record of 27.30% under 5.9 sun illumination. This strategy showed the potential of perovskite hot carrier solar cells in efficient photoelectric conversion.

The currently dominant solar cell is a silicon solar cell, but its conversion efficiency is close to the limit. In order to improve the conversion efficiency, perovskite/silicon tandem solar cells have emerged (Figure 4d) [56]. Although the conversion efficiency of perovskite materials is not yet completely satisfactory, combination with silicon stacks can significantly improve efficiency and reduce cost and power consumption in the fabrication processes [162–165]. Perovskite/silicon tandem solar cells are divided into four-terminal and two-terminal structures. The four-terminal structure consists of two independent perovskite and silicon cells connected in series, and each cell has independent electrical contacts. The two-terminal structure is connected by a two-terminal interconnection method, which simplifies the structure and helps to reduce manufacturing costs.

Commonly used perovskite materials include methylamine lead iodine (MAPbI3), formamidine lead iodine (FAPbI3), and cesium lead iodine (CsPbI3). Among them, MAPbI3 has been widely studied due to its high absorption coefficient and good carrier transport performance, but it is easy to degrade; FAPbI3 is more stable; CsPbI3, as an all-inorganic material, has higher thermal stability but is more sensitive to moisture. Silicon crystal bottom cell materials mainly include C-Si, thin film silicon (TF-Si) and heterojunction silicon with an intrinsic thin layer (HIT-Si) [166]. The perovskite layer is usually processed by solution processing techniques, such as spin-coating and evaporation, to form a uniform perovskite film. The fabrication processing of the silicon layer includes the preparation of C-Si and the deposition of thin film silicon. Common methods include plasma-enhanced chemical vapor deposition (PECVD) and sputtering [167–169].

In the polysilicon-based passivation contact structure, the doped polysilicon layer produced severe light loss due to reflection and parasitic absorption, which hindered the efficiency improvement of solar cells [170,171]. In 2019, Ramírez Quiroz et al. [172] introduced a new interface molecular engineering method based on stacked monolithic perovskite/silicon tandem solar cells. By using a composite material of poly (3,4-ethylenedioxythiophene):poly (styrenesulfonate) (PEDOT:PSS) and D-sorbitol as a transparent conductive adhesive layer, a high-efficiency solar cell with a filling factor of 80.4% was achieved. The prepared monolithic two-terminal perovskite/silicon tandem solar cell showed a steady-state efficiency of 21.0%. Its open-circuit voltage loss was negligible as compared to the single-junction device. In 2024, Ding et al. [173] used PECVD and nitrous oxide as the oxygen source to improve the optical properties of polysilicon through in-situ oxygen doping (Figure 4e). After applying optimized P-type oxygen-doped polysilicon, the short-circuit current density and efficiency of the bottom cell were increased by about 0.32 mA cm−2 and 0.8%, respectively, and achieved a tandem cell efficiency of 25.12%. Till now, the highest efficiency of the two-terminal perovskite/silicon tandem solar cell has exceeded 34%, which was reported by Longi Green Energy Technology Co., Ltd.

Currently, researchers have widely used solar cells in energy-autonomous systems. In 2021, Zhao et al. [174] reported a safe, flexible, and self-powered wristband system that integrates zinc-ion batteries with perovskite solar cells. By integrating zinc-ion batteries with perovskite solar cells, a self-powered wristband system that could harvest light energy and power a commercial smart wristband was constructed, as shown in Figure 4f. This integration not only provided the strategy to solve energy and environmental problems, but also made the entire system free of external power supply. Li et al. [175] optimized the device structure and film fabrication of Sb2Se3 solar cells and prepared mini modules for powering IoT devices. The prepared Sb2Se3 solar cells achieved an efficiency of up to 6.13% and a power per unit weight of 2.04 W g−1. The researchers built the first 25 cm−2 Sb2Se3 mini-module and successfully applied it to power blue LEDs and flower monitors (IoT sensors) under various weather conditions (Figure 4g). In 2024, Hailegnaw et al. [176] prepared an ultra-light perovskite solar cell for drones. The research team achieved a specific power of up to 44 W g−1 and good stability by optimizing the photoactive layer and substrate of the solar cell. Twenty-four 1 cm2 solar cells were interconnected and integrated into the drone, enabling it to achieve energy-self-sufficient flight.

Table 3 lists the recent results of solar cells. The above research works have made significant progress in the field of solar cells in MESOC, especially in improving efficiency and integration. At present, the conversion efficiency of silicon-based solar cells is approaching the theoretical limit. Although new materials such as perovskite have shown high efficiency under laboratory conditions, their ambient air stability and long-term service life in practical applications still need to be further improved. The cost and reliability issues of these materials in large-scale manufacturing are also obstacles to their massive production and application. At the same time, the energy output of solar cells is highly dependent on lighting conditions, which greatly reduces the collected energy in poor light environments such as indoors or cloudy days. In the future, with the advancement of nanotechnology and material science, these shortcomings will be modified and the high-performance solar cells will provide new opportunities for MESOC and promote their widespread use in advanced microelectronic devices.

The material, preparation method, device size, highlights, open circuit voltage and photoelectric conversion efficiency (PCE) of solar cells reported in the literatures

Radio frequency energy harvesters

Radio frequency energy harvesting (RF-EH) is a technology that captures and converts surrounding radio frequency (RF) signals (mobile phones, Wi-Fi, wireless local area networks, broadcast television signals or digital television systems and frequency modulation/amplitude modulation radio signals) into electrical energy [177]. RF energy is independent of weather and location and can be collected by RF-EH systems. This technology serves as an energy harvesting device for MESOC and is expected to be a potential alternative energy source for future applications. RF energy is available over a wide range of frequency bands, including Wi-Fi (2.4 GHz Band, 5 GHz Band), global system for mobile communications (GSM) 900, GSM 1800 and millimeter wave in the frequency range from 30 to 300 GHz [178–180].

The RF energy harvester consists of a receiving antenna, rectifier, and impedance-matching circuit, as shown in Figure 5a [181]. The receiving antenna is used to collect RF signals in the surrounding environment and convert the RF energy into electrical signals. The rectifier converts the received electrical signal into direct current (DC) power. Impedance matching circuits are used to ensure impedance matching between the RF energy harvester and other circuits or devices. Maximizing the capture and conversion efficiency of RF energy is achieved by adjusting the input and output impedance of the collector [182–184]. Receiving antennas are generally made of highly conductive metals such as copper or aluminum to ensure efficient energy capture and transmission. Rectifier circuit materials should have good semiconductor properties, such as silicon or gallium arsenide, which can effectively convert RF signals into direct current [185–188].

|

Figure 5 RF-EH for energy harvesting in MESOC. (a) RF-EH system [181]. Copyright©2022, MDPI. (b) Dual-band RF energy harvester using system packaging technology [190]. Copyright©2017, IEEE. (c) Simulation and measurement results of a dual-band Koch fractal monopole antenna [192]. Copyright©2018, International Journal of Antennas and Propagation. (d) Differential RF-EH system [193]. Copyright©2018, IEEE. (e) Intelligent environment sensing RFID enhancement module [57]. Copyright©2014, IEEE. |

RF energy harvesters usually use CVD or sputtering techniques to deposit conductive metal on a substrate to form an antenna structure. Photolithography is used to prepare a rectifier circuit on a semiconductor wafer, and its electrical performance is improved through a doping process. Then, the rectifier circuit is connected to the antenna, and the energy storage device is integrated into the same circuit board. Finally, packaging technology is used to protect the entire circuit system to ensure its stable operation in various environments.

With the development of wireless communications, the density of RF energy will continue to increase over a wide frequency range, so RF-EH technology has been widely studied [189]. In 2017, Li et al. [190] proposed the compact dual-frequency RF-EH in which the matching network and band-stop filter (BPF/BSF) were implemented on the low-loss integrated passive device carrier and the rectifier was implemented by using 0.18 μm complementary metal oxide semiconductor (CMOS) technology (Figure 5b). The RF-EH device in this study was more compact than previous reports and was expected to be integrated into MESOC. It also made it possible to achieve a higher impedance change rate between the source resistance and the rectifier input impedance, thereby providing higher voltage gain and greatly improving RF-DC conversion efficiency (12.6%). In the same year, Shen et al. [191] designed a dual-port three-band l-probe microstrip patch rectenna design that could collect ambient RF energy in three bands: GSM900, GSM-1800, and UMTS-2100. They stacked two single-port patch antennas back-to-back into a compact two-port l-probe patch antenna. Each port could independently pick up RF signals from half-space with a gain greater than 7 dBi. With the two ports together in a DC combo configuration, the antenna could collect RF energy from nearly all directions. In 2018, Zeng et al. [192] prepared the dual-band rectenna with a compact structure, high efficiency, low cost, and easy manufacturing for RF energy harvesting. The monopole antenna consisted of a longer curved Koch fractal unit in the GSM900 frequency band and a shorter radiating unit in the GSM1800 frequency band, as shown in Figure 5c. The peak efficiencies of the prepared rectenna were 62% and 50% at 0.88 and 1.85 GHz, respectively, and the power densities were 15.9 and 19.1 μW cm−2. When the distance was 25 m from the cellular base station, the output voltage was 1.275 V, which could power the battery-free LCD watch. Arrawatia et al. [193] proposed a gain-enhanced differential microstrip antenna for RF-EH (Figure 5d). The antenna had a gain of 8.5 dBi at the center frequency, the voltage standing wave ratio (VSWR) ≤ 2 over the frequency range of 870 MHz to 1.05 GHz, with an efficiency of 80%. The research team developed the complete differential RF-EH system with a load of 3 kΩ and a peak efficiency of 65.3%. In 2023, Derbal et al. [194] designed a high-gain circularly polarized (CP) hexagonal antenna array for RF-EH. The operating frequency of the hexagonal antenna array was 5.8 GHz. It consisted of 6 multi-layer substrate CP antennas, excited by an x-shaped hole coupling feed structure and added frequency selective surface, with a maximum gain of 12.7 dBi per device. The antenna array had high gain in all directions without using any additional circuitry, allowing it to effectively absorb ambient RF energy. With the use of a DC combiner, the total RF to DC efficiency of the array was 67.75%, with a DC output voltage of 1.115 V from −10 dBm has been recorded.

In 2014, De Donno et al. [57] designed a radio frequency identification (RFID) augmented module for smart environmental sensing (RAMSES). Integrated RF-EH circuit and RFID in the same circuit. In passive mode, RAMSES could collect RF energy emitted by an interrogator placed at a distance of 10 m and autonomously perform sensing, computing and data communications (Figure 5e). In 2020, Vital et al. [195] integrated a rectenna array into wearable textiles and achieved an RF-to-DC conversion efficiency of 70%. The measured aggregate power at 60 cm was 80 μW, which could power three LEDs. It was demonstrated that the system could also charge SC or power sensors. In 2021, Wagih et al. [196] prepared a highly miniaturized flexible rectenna for textile-integrated RF-EH, which increased the total harvested energy five times under the same harvested area. The prepared RF-EH module demonstrated wireless charging of bluetooth low-energy sensor nodes at a distance of 1 meter from the transmitter. The 14.1 mF SC was charged to 4.14 V in 83 s using the rectenna, the incident power density was 23.9 μW cm−2, and the average efficiency exceeded 40%. The sensor node continued working for 108 s after the RF source stopped.

Table 4 lists the recent results of RF-EH devices. The above research works have made significant progress in RF-EH in MESOC, laying the foundation for the realization of wireless power transmission and self-powered equipment. However, the energy conversion efficiency of RF-EH is generally low, especially in the case of low-power signals. Since the RF signals are usually weak, it is difficult for RF collectors to effectively capture and convert enough energy in long-distance situations. In addition, RF-EH is mainly concentrated in a specific frequency range, but the RF signals in the environment have different frequencies. To achieve effective collection and conversion of multi-band signals, it is necessary to develop antennas and matching circuits with wider frequency responses. At the same time, when integrating RF-EH in MESOC, it is necessary to consider the interference caused by other modules to ensure the stability of signal reception and energy conversion. Solving these problems not only requires innovation in materials and design, but also requires the combination of advanced circuit and algorithm optimization technologies to improve the efficiency and reliability of energy harvesting, thus promoting the widespread applications of RF-EH in MESOC.

The antenna structure, thickness, working frequency, working efficiency and highlights of RF-EH reported in the literatures

ENERGY STORAGE DEVICES

Energy storage devices are the key component in ensuring the continuous and stable operation of microelectronic devices, thus playing a vital role in MESOC [197–200]. MESOCs are usually faced with dynamic energy demands to not only receive irregular energy inputs but also provide stable power output to the loads [201–204]. Energy storage devices play the role of balancing the difference between supply and demand, storing excess energy for subsequent use [205,206]. There are two main types of mainstream energy storage devices, namely storage batteries and SC [207]. In this section, we summarized the recent developments of energy storage devices and their applications in MESOC.

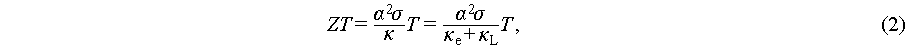

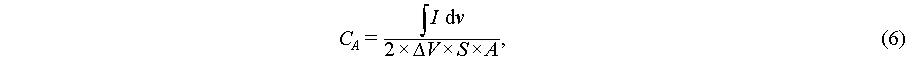

Energy storage battery

MESOC often rely on energy harvesters to obtain energy from the environment, but the energy harvesting process may be affected by environmental factors, such as solar energy, thermal energy, and mechanical energy. Energy storage batteries can store excess energy and release energy when energy collection is insufficient, thereby balancing energy supply and demand and ensuring stable power supply for the following loads [208,209]. As the main choice for powering advanced miniaturized devices, micro energy storage batteries can meet the demand. Currently, researchers have developed various types of energy storage batteries in MESOC, such as lithium-ion batteries and zinc-air batteries. Lithium batteries store and release energy through the movement of lithium ions between the positive and negative electrodes. During charging, lithium ions migrate from the positive electrode (usually lithium compounds) to the negative electrode (carbon material, etc.), and vice versa during a discharge process (Figure 6a) [58]. The chemical reaction equations of lithium battery are shown in Eq. (5) [210,211]:

|

Figure 6 Energy storage batteries used in MESOC. (a) Schematic diagram of how a lithium-ion battery works [58]. Copyright©2021, IOP Publishing. (b) Working principle diagram of water-based and non-water-based metal-O2/air batteries [212]. Copyright©2020, Royal Society of Chemistry. (c) Atomic layer deposition of the functional layer of 3D lithium-ion all-solid-state micro battery on the chip [226]. Copyright©2016, Wiley. (d) A 3D on-chip lithium-ion battery collector was prepared by the orthogonal plowing/extrusion method [228]. Copyright©2019, American Chemical Society. (e) All-solid sponge extruded zinc-air battery [229]. Copyright©2019, Elsevier. (f) Schematic diagram of a lithium-ion battery integrated into a MESOC [233]. Copyright©2017, Wiley. (g) Schematic diagram of intelligent sheath and circuit diagram of two power supply modes [235]. Copyright©2024, Wiley. |

(5)

(5)

where M represents the transition metal element or composite oxide in the positive electrode material, and A represents the negative electrode material.

Lithium batteries usually have high energy density and a good cycle lifetime (500‒800 times), but they will gradually decay due to side chemical reactions during charging and discharging. However, lithium is a relatively expensive and rare material. Various resource-rich alkali metal-ion batteries have been explored as possible replacements for lithium. Zinc-air battery is a battery that uses a chemical reaction between zinc and oxygen in the air to generate electricity (Figure 6b) [212]. In a zinc-air battery, zinc acts as the anode, oxygen acts as the cathode, and the electrolyte acts as the conductor between the battery poles. Zinc-air batteries have a long cycle lifetime (300‒500 times), but due to the expansion and contraction of zinc during the reaction, battery performance may decrease [213–215].

The preparation methods of miniaturized lithium-ion batteries include PVD, pulsed laser deposition (PLD), CVD, and atomic layer deposition (ALD). Among them, ALD technology is widely used to prepare high-quality thin film electrodes because it can accurately control the thickness and uniformity of the film. In addition, printing technologies such as ink-jet printing and direct ink writing (DIW) are also used to manufacture complex 3D structural electrodes. Through these advanced manufacturing technologies, the integrated applications of miniature lithium-ion batteries in microelectronic devices can meet the requirements for volume, shape, mechanical properties, and environmental adaptability [216–220].

Miniaturized lithium-ion batteries are mainly composed of nano- and microscale electrode materials, such as carbon materials (such as CNT and graphene), tin oxide, tin nitride, lithium titanate, and silicon-based materials. CNT with high specific surface area and good conductivity is widely used as negative electrode materials in micro lithium-ion batteries. Tin oxide and tin nitride are also commonly used as conversion electrode materials due to their high specific capacity and stability. Lithium titanate, as an embedded negative electrode material, has excellent chemical stability and cycle lifetime, while silicon-based materials have attracted much attention due to their high theoretical capacity, but the problem of volume expansion (structural fracture) during charging and discharging cycles needs to be solved. In order to enhance the electrochemical properties of the electrode, these materials are usually mixed with conductive additives (such as graphene and CNT) to form a 3D conductive network to promote the transmission of ions and electrons. Currently, researchers are exploring new materials (such as lithium titanate) and developing new solid-state electrolyte materials (such as LiPON and LiSiON) to improve the ionic conductivity and electrochemical stability. These materials have a wide electrochemical stability window and good interface compatibility with significantly reduced self-discharge properties. At the same time, methods such as interface modification, heat treatment, and nanostructure design were used to reduce interface resistance and improve ion transmission efficiency [221–224].

In order to ensure that the MESOC can achieve high performance and reliable power supply in a limited space, energy storage micro-batteries have been extensively studied by scientific researchers [213,225]. In 2016, Létiche et al. [226] used ALD to coat the anatase TiO2 negative electrode on a 3D tube of Li3PO4 lithium phosphate as the electrolyte for the first time. They analyzed the interface between the functional layers by X-ray nanotomography and transmission electron microscopy (Figure 6c). The proposed structure (high area amplification factor—‘thick’ 3D layer) significantly increased the surface capacity from 3.5 μAh cm−2 for planar layers to up to 0.37 mAh cm−2 (105 times higher) for 3D films. This study provided an attractive design for preparing 3D lithium-ion micro-batteries for MESOC, which helped to improve the performance of micro-batteries and expanded their application fields. In 2019, Li et al. [227] discovered that the layered potassium vanadium oxide KxV2O5·nH2O had an amorphous/crystalline dual-phase nanostructure and showed potential as a high-performance anode material for water-rechargeable potassium-ion micro-batteries. This unique nanostructure facilitated the accessibility/transportation of the host hydrated potassium ions, significantly improving the actual capacity and rate performance. A potassium-ion micro-battery with KxV2O5·nH2O as anode and KxMnO2·nH2O as cathode exhibited an ultra-high energy density of 103 mWh cm−3. Yuan et al. [228] prepared a 3D chip-structured current collector using the orthogonal plowing/extrusion method and applied it into lithium-ion batteries (Figure 6d). This on-chip structured current collector avoided the introduction of additional layers or components, eliminated complex manufacturing and integration processes, and provided rich surface structures. After 200 cycles at a current density of 0.2 C, the prepared current collector has a capacity retention rate as high as 98.6%. A high reversible discharge specific capacity of 341.8 mAh g−1 was promoted after 200 cycles. The surface microstructure of the new current collector had a great impact on the adhesion of electrode materials and could provide higher interface bonding strength. After 100 cycles, the capacity retention rate of the electrode was 79.6% at 0.2 C.

As for Zinc-air batteries, in 2019, Pan et al. [229] prepared a compressible all-solid-state ZnO air battery by directly depositing Fe-doped Co3O4 nanowires in an alkaline medium (Figure 6e). A highly squeezable all-solid-state zinc-air battery was assembled using Fe-Co3O4 NWs@NCFs as the air electrode and Zn NSs@NCFs (electrodeposited Zn nanosheets on NCFs) as the Zn electrode. The zinc-air battery featured high open circuit potential (1.51 V), low charge-discharge voltage gap (0.657 V at 5 mA cm−2), and high power density (260 mW cm−2). The battery was able to maintain excellent performance under 60% compressive strain for 500 cycles. This highly squeezable and rechargeable zinc-air battery opened new avenues for energy storage and applications in elastic MESOC. In 2021, Sun et al. [230] reported the zinc-O2/zinc peroxide (ZnO2) chemistry that proceeded via the 2e−/O2 process in a non-alkaline aqueous electrolyte, enabling highly reversible redox in zinc-air batteries reaction. The constructed non-alkaline zinc-air battery not only operated stably in ambient air, but also exhibited better reversibility than alkaline batteries. In 2024, Wang et al. [231] used an extended synthesis method to prepare mesoporous carbon with a high specific surface area (1081 m2 g−1) as the cathode in a zinc-air battery. Compared with commercial carbon black-based cathodes, the energy efficiency (73%), rate performance (no significant voltage fluctuations at all current densities), and cycle life (540 h) of the battery were significantly improved. In addition, mesoporous carbon helped to build a better three-phase reaction interface and improved the electrochemical reversibility. Li et al. [232] developed a lithium-sulfur (Li-S) microbattery with a customized configuration using 3D printing technology. The battery consists of a printable lithium anode with a graphene aerogel framework and a printable sulfur cathode based on a carbon nanocage framework, which showed a rich porous structure with a large specific surface area. The 3D printed Li anode achieved a long cycle life of more than 900 h at an ultra-high current density of 10 mA cm−2 with a low overpotential, while the 3D printed S cathode provided an ultra-high capacity of 21.9 mAh cm−2 at a high thickness of 2.3 mm.

In 2017, Liu et al. [233] integrated the energy harvesting device and storage device while maintaining a small volume and low manufacturing cost. A complex MESOC was presented by mixing inside a solid lithium-ion battery and a triboelectric nanogenerator (Figure 6f). Among them, TiO2 nanotubes served as the anode of the lithium battery, and PEO-LATP solid electrolyte and LiMn2O4 nanoparticles served as the cathode in the lithium battery. The triboelectric nanogenerator could deliver a peak output of 7.4 mW at a load resistance of 7 MΩ. The system could be mounted on a human shoe and continuously drove a green LED, demonstrating the potential of MESOC in movement monitor. Liu et al. [234] prepared a unique TiO2 nanowire array grown on carbon textiles (NAs/CT) as an independent cathode for the fabrication of flexible Li-O2 batteries. The battery achieved superior electrochemical performance even under strict bending and twisting conditions, and stably lighted up LED screens. In 2024, Su et al. [235] integrated Zn/PANI@Pt/C batteries into a self-powered “smart jacket” (Figure 6g). Three batteries were connected in series to power an electric oximeter, which could meet daily medical and health monitoring needs. Four batteries connected in series could power smart electronic devices such as smartphones. This work provided a promising strategy for designing ultrafast air-based self-charging energy storage devices.

Table 5 lists some important research results of energy storage micro-batteries. The above research work has made significant progress in micro-lithium or zinc batteries, promoting the development of miniaturized energy storage devices with high energy density and stable voltage output. However, there are still some shortcomings and challenges in the current applications of lithium batteries in MESOC, including electrode miniaturization, stable loading of active materials, and compatibility of the manufacturing process. In addition, safety issues of lithium batteries (such as flammable organic electrolytes and dendrite formation) and the trade-off between energy density and power density still need to be further optimized. However, this also provides new opportunities for future research to improve overall performance and safety by exploring new electrode materials and manufacturing processes.

The anode, cathode, preparation method, capacity and cyclic stability of energy storage batteries reported in the literatures

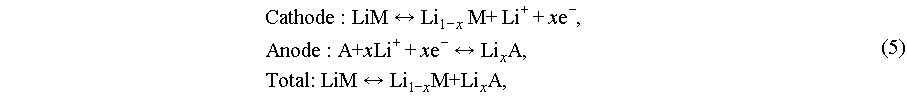

Supercapacitor

SC are considered as promising energy storage devices due to their high energy density, fast charge/discharge rate, and long service life [236–238]. Integrating SC into MESOC can efficiently store excess energy and provide stable power output for MESOC [239,240]. SC are usually composed of electrodes (including active materials and current collectors), electrolytes, and separators to provide fast charge/discharge cycles. Its performance depends on the intrinsic properties of the materials used and how the components are assembled into a complete device. The performance of SC is usually expressed in terms of three parameters: specific capacitance (CA), energy density (E), and power density (P), which can be calculated by Eqs. (6)–(8) [241,242].

(6)

(6)

(7)

(7)

(8)

(8)

where  is the integral area of the CV curve, A is the projected area of the electrode (cm2), S is the scan rate (V s−1),

is the integral area of the CV curve, A is the projected area of the electrode (cm2), S is the scan rate (V s−1),  is the voltage window (V), and

is the voltage window (V), and  is the discharge time (s).

is the discharge time (s).

Based on the energy storage mechanism, SC can be categorized into three types: electric double-layer capacitor (EDLC), pseudo-SC, and hybrid SC [243]. EDLC stores energy through reversible adsorption/desorption of ions at the interface of the electrodes and the electrolyte, which allows for very fast charging/discharging rates and long-term operational stability [244]. Pseudo-SC stores charge on the electrode surface through a reversible redox reaction. Hybrid SC combines EDLC and pseudo-reactions to increase the electrochemical performance of the capacitor [245].

The commonly used electrode materials for SC mainly include carbon materials, transition metal oxide (TMO), and conductive polymer (CP). In terms of electrode materials, activated carbon (AC), CNT, and graphene are often used in EDLC [246,247]. In contrast, TMO (e.g., MnO2, NiO, Fe2O3, and Co(OH)2) as well as CP (e.g., polyaniline, polypyrrole, and polythiophene) are often used as electrode materials for pseudocapacitors [207,248]. In addition, some novel materials such as MXene, polymetallic oxides, and black phosphorus are considered as potentially efficient electrode materials for SC due to their unique properties. The latest SC research mainly focused on transition metal chalcogenides (TMC) and their composites. These materials include sulfides, selenides, and tellurides, such as cobalt sulfide (CoS), nickel sulfide (NiS), nickel selenide (NiSe), and vanadium sulfide (VS2) [86,249]. These materials exhibited excellent electrochemical performance due to their high electrical conductivity, multiple oxidation states, and excellent redox properties. By combining TMC with carbon-based materials, such as graphene and carbon nanotubes, the specific capacitance, power density, and cycle stability of SC can be greatly improved. At the same time, the application of synthesis technologies such as hydrothermal, solvothermal, and co-precipitation methods has enabled the development of nanostructured materials. These structures, such as nanorods, nanosheets, and nanotubes, increased the surface area of the materials, promoting faster ion diffusion and electron transport, resulting in significantly improved charge and discharge efficiency and energy density of SCs.

As energy storage elements are integrated into microchips, SCs must have sufficient energy and power density. To improve the performance of SCs, many methods have been taken from structural design to manufacturing, such as multi-layer thick electrodes, 3D interdigital electrodes, nanostructured hybrid materials, hierarchical porous materials. For example, Shao’s group developed a series of modulation methods of graphene materials for high-performance SCs, like turbostratic graphene [250], sphere-like graphene [251], and spark-induced graphene [252] to facilitate ion accessibility and transport, consequently benefiting electrochemical performances. At the same time, electrode construction and active mass loading methods, such as micromachining, laser irradiation, 3D printing, and screen printing, have also been developed [253,254]. For example, fast ion transport channels like microholes and microcracks are conducted to accelerate ion diffusion and mass loading [255,256].

For on-chip SC, the stability and safety of the electrolyte have to meet the requirements of the manufacturing and usage environment. Therefore, leak-free solid or gel-type electrolytes are preferred [257]. The most widely used gel electrolyte material for on-chip SC is polyvinyl alcohol (PVA). However, the infilling of gel electrolytes into porous electrodes is usually a tricky issue. To this end, innovative strategies like the bottom-up infilling method and in-situ gelation are proposed to form excellent interfaces between gel electrolyte and electrode pores for electric double-layer (EDL) sites [258,259].

Meanwhile, novel hydrogel electrolytes are also being explored in research to further enhance the performance [260]. Planar interdigital electrodes are often used when integrating SCs into on-chip energy systems (shown in Figure 7a) [59]. Compared with the sandwich structure, the planar structure can effectively reduce the ion diffusion length, fully utilize the electrode materials, and enhance the electrochemical performance of SC [261–264]. In addition, SC with planar structures are more easily compatible with microelectronic devices.

|